Prefabricated wall panels, like Sto Panel Technology® prefabricated wall panels, offer architects and builders a superior solution to many of the challenges of healthcare construction, ensuring the projects stay on time and within budget while meeting safety and code requirements. Prefabrication also offers architects a sustainable and long-lasting complete building envelope system in an expansive range of aesthetic choices.

Prefabrication Hastens the Construction Timeline

A community’s growing need for medical care and minimizing disruptions to healthcare professionals, patients, and visitors during construction often demands quick timelines for healthcare construction projects.

Fortunately, prefabrication is a solution to faster construction timelines than conventional construction:

- Prefabricated panels are manufactured in a controlled manufacturing environment, eliminating weather or other field conditions that can cause delays to construction schedules.

- Producing panels in quality-controlled factories allow for inspection, testing, and checking of the building envelope before panel installation on the project.

- Prefabrication allows builders to quickly complete a vertical expansion of a healthcare building.

- Completed wall panels take days or weeks to install, not months, like traditional construction.

Prefabrication Helps Healthcare Projects Stay on Budget

Construction projects represent a significant part of a health care organization’s budget, with costs running from thousands to millions. Therefore, for the financial stability and success of the healthcare facility, the building project must stay on budget.

- Builders can save money with prefabricated panels because the lightweight panels lessen job site labor, require fewer specialized trades, minimize the use of scaffolding, and allow for fewer structural needs.

- Prefabrication minimizes construction waste and debris to save money.

- Prefab wall panels often offer a single-source warranty, giving owners added protection and peace of mind.

Sustainable, Prefabricated Wall Panels

A sustainable health care facility aims to reduce energy and water consumption, limit carbon emissions, and create long-lasting buildings – all features that save money and time spent repairing or rebuilding. Energy-efficient, durable, prefabricated wall panels can significantly contribute to a sustainable healthcare facility. In addition, builders can quickly retrofit an existing building with prefabricated wall panels as an aesthetic, economical, and energy-saving sustainable alternative to new construction.

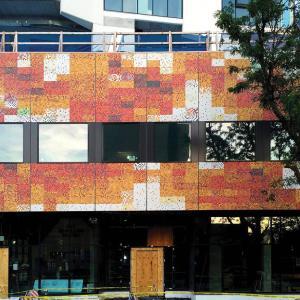

Aesthetic Flexibility of Prefabricated Wall Panels

A well-designed, aesthetically pleasing healthcare facility helps attract and maintain patients and enhance a patient’s experience satisfaction. It can also reduce stress, improve a patient’s sense of well-being, and even boost their immune system.

Prefabrication offers architects several significant aesthetic advantages:

- Prefabrication offers aesthetic flexibility, from a modern, lightweight, energy-efficient coating system to classic brick, stone, and metal.

- Prefabrication design flexibility allows architects to match the aesthetics of the original building.

Inspira Medical Center, Vineland, NJ, Jersey

Owner: Inspira Health Network

General Contractor: Skanska

Architect: Array Architects

Prime Building Envelope Contractor: Jersey Panel

Building Type: Healthcare

On-Site Assembly Date: October 2019

Panel Type: StoPanel® Classic NExT ci, StoPanel® Metal ci, StoPanel® Brick ci using Stone Veneer

Jersey Panel, Array Architects, and Inspira Health Network utilized the integrated project delivery (IPD) design and construction approach to address the construction and aesthetic challenges in the vertical expansion (two floors) of the Inspira Medical Center. An IPD project delivery approach involves all the building team members collaborating through all design, fabrication, and construction phases to optimize the project’s results.

The team chose prefabricated lightweight, energy-efficient, and durable Sto Panel Technology® prefabricated wall panels. Jersey Panel engineered, fabricated, shipped, and installed 121,000 ft2 of prefabricated wall panels in the construction of the Inspira Medical Center. They combined flat and radiused panels, a microtextured self-cleaning finish, and a thin stone veneer to create a dynamic appearance.

The StoPanel® system panels consist of cold-formed metal framing and other applicable components, including continuous insulation (ci), glass mat sheathing, air and water-resistive barrier, sub-framing, and facade aesthetic. Sto prefabricated wall panels offered the building team many advantages:

- By fabricating multiple claddings off-site, prefab panels significantly reduced on-site labor costs while exceeding the installation schedule, contributing to completing the project on time and within budget.

- The close proximity of the Jersey Panel’s facility allowed them to fabricate and transport extra-large panels (35′ W x 16.5′ H) to the job site, further hastening the completion time and helping to control costs.

- Only a crane and a crew of approximately six workers were required to erect the entire exterior facade in less than two weeks – a significant advantage in today’s tight labor market.

- Minimized disruptions to the healthcare professionals, patients, and visitors,

- Prefabrication reduced the amount of waste and debris from traditional field-built projects.

- StoPanel® system panels allowed architects to match the new construction with the aesthetics of the existing one-story building and the main nearby hospital building.

- It met the client’s aesthetic requirements of various textures and materials, like corrugated metal, stone, limestone, and wood-grain metal.

- The addition also called for a new element to the building’s aesthetics, metal panels. Architects choose StoPanel® Metal ci for this feature.

Download the full Inspira Medical Center case study here.

StoPanel® Brick

StoPanel® Brick prefabricated wall panels include steel framing, gypsum sheathing, thin masonry veneers, or thin brick.

StoPanel® Metal

StoPanel® Metal prefabricated wall panels include steel framing, gypsum sheathing, and metal façade

UCF Lake Nona Medical Center, Orlando, Florida

Owner: UCF / HCA

General Contractor: Layton Construction

Architect: ESa

Wall Panel Engineer: FDR

Prime Building Envelope Contractor: Wal-Mark Contracting Group

Building Type: Healthcare / Hospital

On-Site Assembly: Date 2019

Panel Type: StoPanel® Classic NExT ci / StoPanel® Impact ci panels

The threat of hurricanes and tropical storms constantly looms over Central Florida. Therefore, the design of the UCF Lake Nona Medical Center’s building envelope, including the exterior facade, had to meet stringent wind-load and impact requirements.

Architects also had to ensure that the project stayed on schedule and budget. Other challenges to the project included installing curtain walls and glazed openings alongside the erected exterior wall panels and limited site access to an extensive number of underground utilities.

Fortunately, StoPanel® Impact ci and StoPanel® Classic NExT ci panels offered a solution to all these challenges.

- Both products meet Florida’s stringent wind load and impact-rated mandates.

- The repeatability and precision of the panels allowed the glazing contractor to pre-order their materials to accommodate the dry-in schedule.

- The StoPanel prefabrication process allowed Wal-Mark Contracting to manufacture and install the panels within an aggressive timeline and with fewer workers. It only took eight panel installation experts to install 136 panels in only eleven days, avoiding underground utilities and exceeding schedule expectations on this challenging project. A traditional field installation would require 30-40 workers, costing more and potentially leading to more job site accidents.

StoPanel® Classic NExT ci

- StoPanel® Classic NExT ci prefabricated wall panel includes steel framing, gypsum sheathing, and StoTherm® ci façade.

StoPanel® Impact ci®

- StoPanel® Impact ci® prefabricated wall panels include steel framing, gypsum sheathing, and StoTherm ci system, designed for small and large missile impact performance.

Download the full UCF Lake Nona Medical Center case study here.

Why Choose Sto Panel Technology for Your Next Healthcare Project?

Sto Panel Technology offers architects and builders of healthcare projects extensive design flexibility while meeting their scheduling, performance, and budget demands.

Our prefabricated wall panels contribute to sustainable, durable, and low-maintenance healthcare buildings, all features that will save money and time.

Download Industry Shift: The Acceleration of Panelization or contact one of our experts today at 800-545-6087.