Rendered facades give a building a sophisticated and sleek look in a wide range of finishes, textures, and colors that will suit any budget and building style. Typically, render cladding systems refer to a coat of cement on a building’s exterior to create a smooth, textured, or patterned finish in an expansive range of colors.

However, complete external render cladding systems (like the StoVentec® Render Rainscreen® wall assembly) provide all the exterior wall system components (air and water-resistive barrier, insulation, sub-construction, and rendered façade panel) into one straightforward-to-install system, which will save builders money and time.

The StoVentec® Render complete Rainscreen® cladding system produces superior air and water resistance, excellent thermal performance, wind, fire, and impact protection, and attractive render aesthetics. Each component contributes to the building’s long-term integrity and indoor comfort, safety, and air quality.

What is Exterior Rendering?

Installers apply a render coating to a façade to create a smooth or textured surface, in order to improve a building’s aesthetics and extend the exterior wall’s lifespan.

Types of Render Finish

The success of a rendering project depends on choosing a suitable render material:

Lime Render

Breathable lime render expands and contracts without damage, and is particularly suited to older buildings that cannot use cement render.

Cement Render

Easy-to-apply, quick curing, and durable cement render prevents water damage and provides walls with added strength. However, its rigidity makes it prone to cracking, so installers typically avoid its use on older structures.

Acrylic Render

Acrylic render sets in just 24 hours, faster than other renders. Various aggregate sizes allow for a variety of aesthetic ranging from smooth to coarse

Monocouche Render

Installers often use easy-to-use, single-layer monocouche rendering on new houses and buildings.

Polymer Render

Installers often use polymer render, which allows the substrate to breathe on most wooden or brick buildings.

Other tips for successfully installing render include:

- Mix the render with room-temperature water.

- Do not apply in extremely hot weather because the render mix will set in too fast, and lead to cracks.

- Do not apply in frigid weather because it will cause the render mix to slide down, and make it messy.

- Mild-cloudy and rain-free days are the best days for using render.

Six Benefits of External Rendering

Properly applied external rendering can provide a building with several long-lasting, significant benefits. However, successful rendering depends on thoughtfully designing and hiring a reputable and skilled installer.

1. Protects a Property Against Rain and Wind

Exterior wall rendering is the first defense against harsh weather and moisture infiltration in a building’s envelope. It can also protect against mold and algae growth.

2. Enhances a Building’s Appearance

External render cladding creates a modern look of luxury. It can also hide unattractive-old brickwork, and give a building a crisp new appearance. Furthermore, rendering allows architects to combine additions to an existing building.

3. Adds Value to a Property

Render facades enhance a building’s curb appeal, which adds value to the property.

4. Cost-Effective Rendering

External rendering offers builders a cost-effective cladding solution. However, it depends on the render type, surface preparation, project location, project size, and the tradesman’s experience. To be cost effective, the climate zone and exposure must be taken into consideration. Opting for a higher end render can save money on the long run with superior durability and fading resistance.

5. Breathable Renders

The breathability of silicon and mineral render facades allows moisture generated from the indoors to evaporate to the outside, which helps to minimize condensation within the wall cavity.

6. Low-Maintenance

Low-maintenance, UV-stable, pre-colored renders can last up to 10 years depending on the climate zone and exposure. Using a super hydrophobic render will also reduce maintenance with its self cleaning properties. In addition, applying the render to a flexible-thin fiberglass mesh base layer allows it to move with the building, which makes it less prone to cracking.

StoVentec® for Render Facades

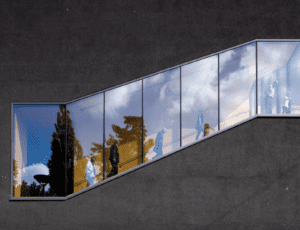

Queensbridge Quarter combined StoVentec® Render and Glass systems to deliver a stunning multi-family building in London.

The traditional method of installing render protects the exterior wall’s durability; however, on its own, it does not improve the building envelope’s thermal performance.

Fortunately, the ®StoVentec® Render Rainscreen® wall system is a complete, fully-tested, code-approved, back-ventilated wall system that provides a superior air and water-resistive barrier and strong mineral wool continuous insulation (CI).

In addition, the drained and back-ventilated StoVentec® Render rainscreen wall assembly offers the aesthetics of Stolit® Lotusan®, Sto textured finish, self-cleaning textured finish, and StoCast prefabricated resin cast shapes.

StoVentec® Rainscreen® Systems

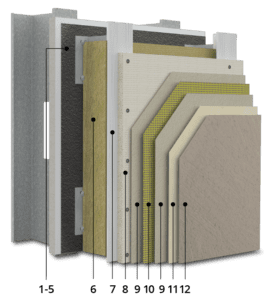

StoVentec® Render Rainscreen® Systems are a complete, fully-tested, and code-approved, ventilated system with extensive design options. Sto’s Rainscreen® systems include a water and air-resistive barrier, an adjustable sub-framing system, non-combustible mineral wool continuous insulation (CI), and our high-quality StoVentec® Rainscreen® cladding. In addition, the lightweight and energy-efficient StoVentec® Rainscreen® Systems reduce heating and air-conditioning costs and limit condensation that can cause unhealthy and damaging rot and mold.

The back-ventilated and drained StoVentec® Render Rainscreen® wall assembly provides the aesthetics of Sto textured finish, self-cleaning textured finish, and StoCast prefabricated resin cast shapes.

1. Air and Water-resistive Barrier – Wall Membrane: Sto AirSeal®

2. Air and Water-resistive Barrier – Sheathing Joints and Corners: Sto RapidGuard®

3. Air and Water-resistive Barrier – Rough Opening Protection: Sto RapidGuard®

4. Air and Water-resistive Barrier – Flashing and Penetration: Sto RapidGuard®

5. Insulation: Owens Corning Thermafiber® Rainbarrier® 45

6. Sub-construction: StoVentro® Subconstruction

7. Carrier Board: StoVentec® Carrier Board A+

8. Base Coat: StoArmat Classic Plus

9. Reinforcing Mesh: Sto Mesh

10. Primer: StoPrime® Sand

11. Textured Finish: Stolit Lotusan 1.5

Alternatives

Stolit 1.5

Stolit Lotusan Freeform

Sto Essence Medium Sand Finish

Sto Essence Swirl Finish

Stolit Freeform

Click here to see all Sto finishes for StoVentec® Render.

Alternatives to Rendering – StoVentec® Render Rainscreen® Systems

StoVentec® Render Rainscreen® systems are a superior solution to beautiful render cladding. StoVentec® Render Rainscreen® produces energy-efficient, sustainable, healthy, comfortable, long-lasting exterior walls. They are complete, thoroughly tested, code-approved, back-ventilated systems that offer:

- A superior air and moisture barrier

- Strong mineral wool CI

- Straightforward installation with an adjustable sub-framing system

- Sto’s high-performing StoVentec® Render Rainscreen® cladding options

In addition to rendering finishes, StoVentec® Rainscreen® systems are also available in glass and masonry veneer, which provides building owners and architects an expansive range of aesthetic options for rainscreen façades combined with Sto’s other highly-engineered components.

The StoVentro™ Rainscreen® sub-construction has a system for uneven substrates that furnishes flush transitions between different rainscreen claddings.

Contact Sto today for more on our superior alternative to traditional rendering facade systems – the StoVentec® Render Rainscreen® systems.