Durable and robust, tempered or toughened glass can enhance a building’s safety and functionality. Fabricators form tempered and toughened glass by heat and chemical treatments, which induces compressive stresses on the glass’s surface to increase the glass’s strength and safety. The safety and strength of tempered or toughened glass make it desirable for various residential, commercial, and institutional architectural and aesthetic applications.

Which fabricated glass product, toughened glass or tempered glass, offers the most benefits over annealed (regular) glass? The answer is neither – tempered glass and toughened glass are different in name alone, and they provide homes, businesses, and institutions with the following benefits and features:

Strength

The manufacturing of tempered and toughened glass involves processing glass under controlled thermal or chemical treatments to increase its strength. Heat treatment can make the glass six times stronger and more impact, wind, and weather resistant than untreated glass – for a safer consumer product. In addition, the code of federal regulations (Consumer Product Safety Commission) cites ANSI Z97.1, which crosslinks to ASTM C1048, mandating that fully tempered glass (Kind FT) achieve a surface compression of 10,000 lbs. in2 (psi) or more, which protects it from breakage up to 24,000 psi. In contrast, annealed glass will break at only 6,000 psi.

Safety

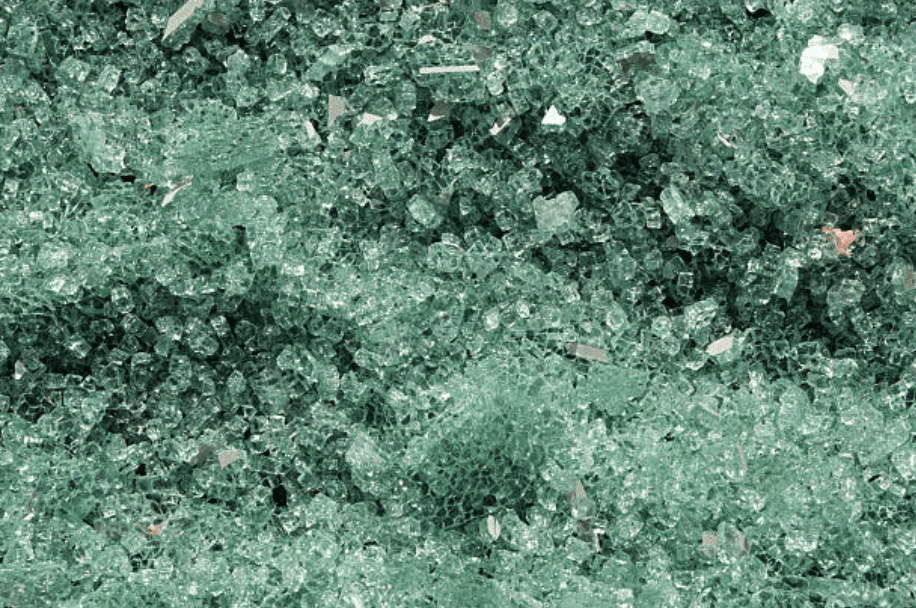

Increasing the compressive stresses on the glass’s surface creates tension in the interior. If the glass breaks, the mechanical stresses cause the glass to crumble into small, smoothed-edged granules that are much less dangerous than regular glass that splinters into jagged shards of plate glass.

U.V. Protection

Tempered (toughened) glass blocks nearly all of the sun’s UVB rays; however only a portion of UVA rays.

Thermal Resistant

Toughened glass can withstand high temperatures or significant temperature differences (thermal shock) without damage compared to regular glass.

Design Versatility

Designers can use versatile tempered glass for many applications, including:

- Balusters, escalators, handrails, staircases, etc.

- Partition for airports, offices, resorts, homes, etc.

- Sliding doors and windows

- Decorative panels in interior design

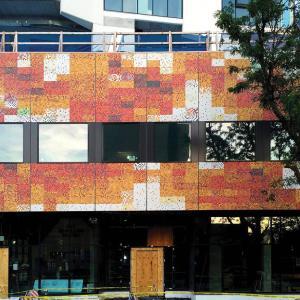

- A building’s facade

Location: Shoreview, Minnesota USA

Building Type: Entertainment & Cultural

System Type: Rainscreen

Systems & Products: StoVentec Glass

Construction Type: Renovation

Construction Method: Field-Built

Case Study: Click Here

Will Tempered Glass Break?

Thermal stress can cause tempered (toughened) glass to break during installation. In addition, a chipped edge can develop into a more extensive break.

How to Make Toughened (Tempered) Glass?

Manufacturers transform annealed (conventional) glass into toughened (tempered) glass by heat or chemical treatments.

Heat Treatment

- Before tempering, fabricators cut the annealed glass to the desired size.

NOTE: Etching or edging tempered glass will reduce its strength, which can potentially lead to product failure.

- Fabricators examine the glass for imperfections that could lead to breakage during tempering.

- Next, the glass moves through a tempering oven that heats the regular glass to a uniform temperature of 600 to 700°C (1112 to 1292 °F) – the industry standard is 620 °C (1148 °F).

- After heating, the glass is placed in an annealing lehr (long kiln), where it undergoes a high-pressure cooling procedure (quenching) in which high-pressure air blasts the glass from an array of nozzles in various positions, cooling it to 60 °C (140 °F). Quenching cools the glass’s outer surface faster than its center.

- As the center cools, it pulls away from the outer surface, which creates tension in the center, compresses the outer surface, and strengthens the tempered glass.

Chemical Treatment

Fabricators use various chemical exchange ions on the surface of the glass to create compression. However, this method produces less strength than the heat treatment. It is also more costly than heat treatments.

Identifying Toughened or Tempered Glass

A stamp in the corner of the sheet of glass identifies the glass as tempered (toughened). The identifier will show the manufacturer’s name and the CPSC (Consumer Product Safety Commission) standards.

To classify as tempered glass, it must achieve a minimum compressive stress on its surface of 69 MPa (10,000 psi). To be considered a safety glass, its compressive stress on its surface must exceed 100 Mpa (15,000 psi), which makes it safe for high-pressure and explosion-proof applications.

StoVentec® Glass Rainscreen® Systems

The StoVentec® Glass Rainscreen® System is a straightforward-to-install toughened (tempered) glass rainscreen opaque architecture system that helps ensure a successful, long-lasting wall assembly of thermally-efficient insulation that limits damaging condensation and lowers the cost of heating and air-conditioning. At the same time, the tempered glass structural frame improves safety against high impact, wind, and fire.

Location: Lake Anna, Virginia USA

Building Type: Residential

System Type: Rainscreen

Systems & Products: StoVentec Glass

Construction Type: New

Construction Method: Field-Built

Case Study: Click Here

StoVentec® Glass Rainscreen® System Components

The StoVentec® Glass Rainscreen® System consists of toughened (tempered) glass-faced composite panels (outer layer) to keep the weather out. Mounting brackets between the panels produce a gap that permits air circulation (ventilation), moisture evaporation, and drainage. Thermal insulation is added within the rainscreen cavity, and a Water Resistive Barrier (WRB) is applied on the exterior wall surface.

Decorative Glass Panel

The durable and decorative toughened glass panel can withstand the weather, and it has four to five times more strength than regular glass. If broken, the toughened glass will break into smaller, safer pieces and stay bonded to the backing board.

Support Structure

The aluminum rails and galvanized or stainless steel brackets carry the panel system and resist wind loads. Aluminum provides a greater strength-to-weight ratio (at less cost), while stainless steel enhances thermal performance. The thermal conductivity of stainless steel is 17 W/m K versus aluminum’s 210 W/m K. Combining aluminum rails and galvanized or stainless steel brackets maximizes performance and cost. The number of brackets depends on the wind loads, the system’s depth, and the substrate’s properties.

Insulation

Insulation (typically made of mineral fibers) insulates the substrate and surrounds the brackets. The insulation minimizes condensation (to eliminate structurally damaging and unhealthy mold), lessens temperature fluctuations, and helps to keep the wall warm.

Continuous Air and Water-Resistive Barrier

A continuous air and water-resistive barrier stops moisture from infiltrating the structural wall. The 2021 IBC mandates a weather-resistant exterior wall envelope for all structures, with a few exceptions like concrete and masonry walls.

However, leaks can occur due to improper installation or deterioration that permits water to flow through tiny openings by gravity, surface tension, capillarity, air pressure differences, and momentum (kinetic energy). A rainscreen cladding system will limit water intrusion by providing a drainage plane.

Improved Safety

Blast-Tested

The strength and integrity of the StoVentec® Glass Rainscreen® System can pass rigorous blast tests, which makes it suitable for public spaces like airports and railway stations.

Wind Resistance

Properly installed galvanized or stainless-steel wall brackets and aluminum horizontal and vertical rails create the sub-construction that form a solid structural link between the supporting wall construction and the facade. This structural design absorbs dead loads and wind and transfers them to the supportive wall construction.

Fire Breaks

Rainscreen installation must comply with fire-resistance testing mandates, like the ASTM E119 and NFPA 285 standards.

Why Choose StoVentec® Glass Rainscreen® Systems?

Robust StoVentec® Glass Rainscreen® Systems contribute significantly towards energy-efficient, safe, low maintenance, and comfortable buildings with healthy I.E.Q.

The StoVentec® Glass Rainscreen® consists of toughened (tempered) glass-faced composite panels (outer layer) that can enhance a building’s safety, strength, U.V. protection, thermal resistance, and design versatility.

Zislis Residence

California entrepreneur Michael Zislis chose StoVentec® Rainscreen® System in Pastel Blue, Light Blue and Azure Blue to make a bold, eye-catching statement for his family’s home.

Atlanta Plant Tank Farm Wall StoVentec Glass Rainscreen System

Download the StoVentec® Glass Design Guide & Detail Booklet today for more on tempered or toughened glass cladding solutions for buildings.