Properly installed liquid-applied air and water-resistive barriers (AWRB) provide all the applicable performance and installation requirements for air and water resistance. An AWRB helps protect the building and its occupants from damaging and unhealthy mold and rot.

Vapor-permeable or impermeable liquid-applied AWRB materials form a membrane upon drying and curing that bonds to the exterior sheathing without fasteners. Liquid-applied AWRB membranes can be used behind any cladding, including: exterior insulation and finish systems (EIFS), glass panels (opaque), fiber cement, brick, stone, stucco, and metal panels. Liquid -applied materials can be used as wall membranes as well as flashings around rough openings, penetrations, etc.

AWRB Performance Requirements

Building codes mandate the performance requirements for AWRB products. They specify that AWRB materials must comply with the 2021 International Building Code (IBC 1402.2) requirements for water resistance and vapor permeability and the 2018 International Residential Code for water resistance (IRC R703.1.1).

Applicators can choose from several qualifying AWRB materials, including self-adhered membranes, concrete, spray foam, building wraps, integrated sheathings, sheet goods, thermal insulation boards, and liquid-applied membranes. Crucial components of a high-quality AWRB include high tear strength, durability, ultraviolet resistance, and straightforward installation.

In addition, accessory materials (reinforcing mesh, tapes, sealants, sheet goods, elastomeric materials, self-adhered membranes, and foam products) can be used in conjunction with liquid-applied AWRB to provide continuity of air or water resistance.

Contact the professionals at Sto today for guidance and assistance in choosing the best liquid AWRB and the right accessories to integrate to achieve a tight building envelope.

Benefits of Liquid-Applied AWRB Membranes

Liquid-applied air and water-resistive barriers provide many advantages that save time and money and help preserve the health and integrity of a building:

Quick Application

A qualified installer can quickly roll or spray the air and water-resistive barrier membrane on the wall to save both time and money. In addition, a spray-applied vapor barrier does not need a primer, which further saves time.

Durable

A liquid-applied AWRB barrier will not lose its integrity when exposed to outside elements during and after construction. Check with the manufacturer’s recommendation for length of exposure.

Permits Complex Detailing

A liquid-applied AWRB efficiently adheres to and waterproofs various wall conditions (e.g., detailed wall openings, penetrations, fasteners, and repair locations), conforms to uneven substrates, and adapts to complex architectural substrate geometry and is the ideal choice when waterproofing critical details.

In contrast, sheet-applied air and moisture barriers need cutting, folding, lapping, and sealing.

Moisture Barrier

When applied at the proper thickness, a liquid-applied vapor barrier produces a seamless moisture barrier by limiting installation errors that can cause lap joints, tears, and holes.

Air Barrier

A liquid-applied AWRB stops air leakage, reduces energy costs and condensation, and improves occupant comfort.

Rainwater Barrier

Liquid-applied barriers for pressure-equalized or pressure-moderated wall design will lower the risk of rainwater penetration through the wall system.

Wind Barrier

A liquid-applied AWRB provides structural and full adherence for rigidity and stability against extreme wind events.

Reduces Repairs

A liquid-applied AWRB membrane protects the sheathing and rough openings from weather damage during and after construction, which reduces repair and replacement costs.

Safe

Safe to use, V.O.C.-compliant AWRB offers easy cleanup.

Sto Liquid-Applied AWRB Membranes and Detail Components

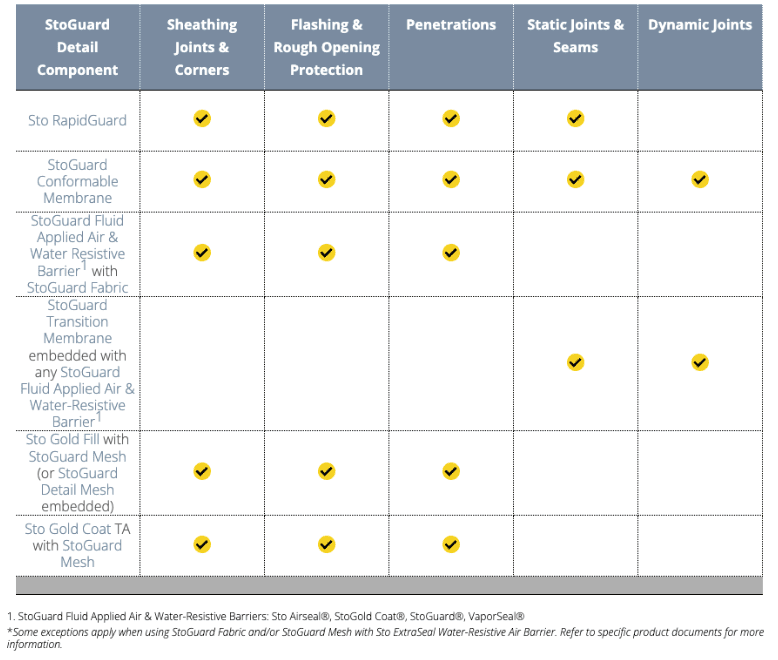

The StoGuard family of air and water-resistive barrier products includes impermeable liquid-applied membranes or vapor permeable air barriers, depending on the wall design and climate: Sto Gold Coat®, Sto AirSeal®, Sto ExtraSeal®, and Sto VaporSeal® – all work as quality water and air barriers when used with StoGuard® Detail Components a set of fully compatible accessories. These Detail Components are designed for use with StoGuard fluid-applied AWRB products at movement joints, substrate transitions, penetrations, transitions to roofing and below-grade air barriers, and rough openings.

Sto Liquid-Applied AWRB Membranes

Sto Gold Coat®, Sto AirSeal®, and Sto VaporSeal® apply easily with a roller or spray, which reduces the required application skill level. Sto ExtraSeal® is trowel-applied.

Sto Gold Coat®

Sto Gold Coat is a vapor-permeable, flexible, ready-mixed fluid-applied membrane that can be installed on various substrates including:

- as part of StoTherm®, StoQuik®, StoPowerwall®, and StoVentec® wall systems and behind most exterior claddings, including rainscreen, metal, wood, stone, brick, and masonry.

- Sto Gold Coat application is available in 3 specifications based on desired thickness: substrate-driven, medium build or high build, depending on the project requirements.

Simply apply Sto Gold Coat® fluid-applied membrane with a roller or spray directly to vertical above-grade wall sheathing and concrete masonry. It functions as a waterproof air barrier when used with StoGuard® Detail Components.

Sto AirSeal®

Sto AirSeal is a flexible, ready-mixed fluid-applied membrane that can be installed on various substrates:

- as part of StoTherm®, StoQuik®, StoPowerwall®, and StoVentec® wall systems and behind most exterior claddings, including rainscreen, metal, wood, stone, brick, and masonry.

- Sto AirSeal application is available in 3 specifications: substrate-driven, medium build or high build, depending on the project requirements.

Sto AirSeal® features 500 percent elongation and meets ASTM C1305 Low-Temperature Crack Bridging requirements. Sto AirSeal®’s unique elasticity of viscosity makes it a superior choice for high-build installations.

Sto ExtraSeal®

Sto ExtraSeal® is a vapor-permeable, Portland cement-based,trowel or spray-applied AWRB that can be applied over prepared above-grade concrete masonry (CMU) and concrete walls beneath StoPowerwall and Sto-listed ASTM C926 compliant stucco brown coats to provide substrate water and air leakage.

Sto VaporSeal®

Sto VaporSeal® is a Class 1 Vapor Retarder that can be applied using a spray or roller on various substrates, including:

- as part of StoTherm®, StoQuik®, StoPowerwall®, and StoVentec® wall systems

and behind most exterior claddings, including rainscreen, metal, wood, stone, brick, and masonry.

Sto VaporSeal® features 500 percent elongation and it meets the requirements of ASTM C1305 Low-Temperature Crack Bridging requirements.

StoGuard® Detail Components, in combination with Sto liquid-applied membranes, provide durable, continuous air and water-resistive barriers at vital areas like penetrations, movement joints, substrate transitions, roofing, transitions to rough openings, and below-grade air barriers. Normal methods are to apply StoGuard® Detail Components and then overcoat them with the liquid-applied membrane.

Why Choose Sto Liquid-Applied AWRB Products?

The Sto roller or spray-applied family of liquid-applied AWRB products gives builders and architects a superior solution to their application and weather barrier design challenges. Our simple-to-apply products save time and money during the application process and maintain their integrity for the building’s lifetime.

Contact our Sto professionals today for more on liquid-applied AWRB and Detail Components!