The construction industry today recognizes the impact of climate science on building design and resilience. As a result, the message is clear: all new and renovation construction must protect the structure and its occupants against increasing weather-related hazards, particularly regarding moisture management.

Fortunately, there’s a comprehensive, proven solution that delivers on these fronts and others. It’s called a Rainscreen System.

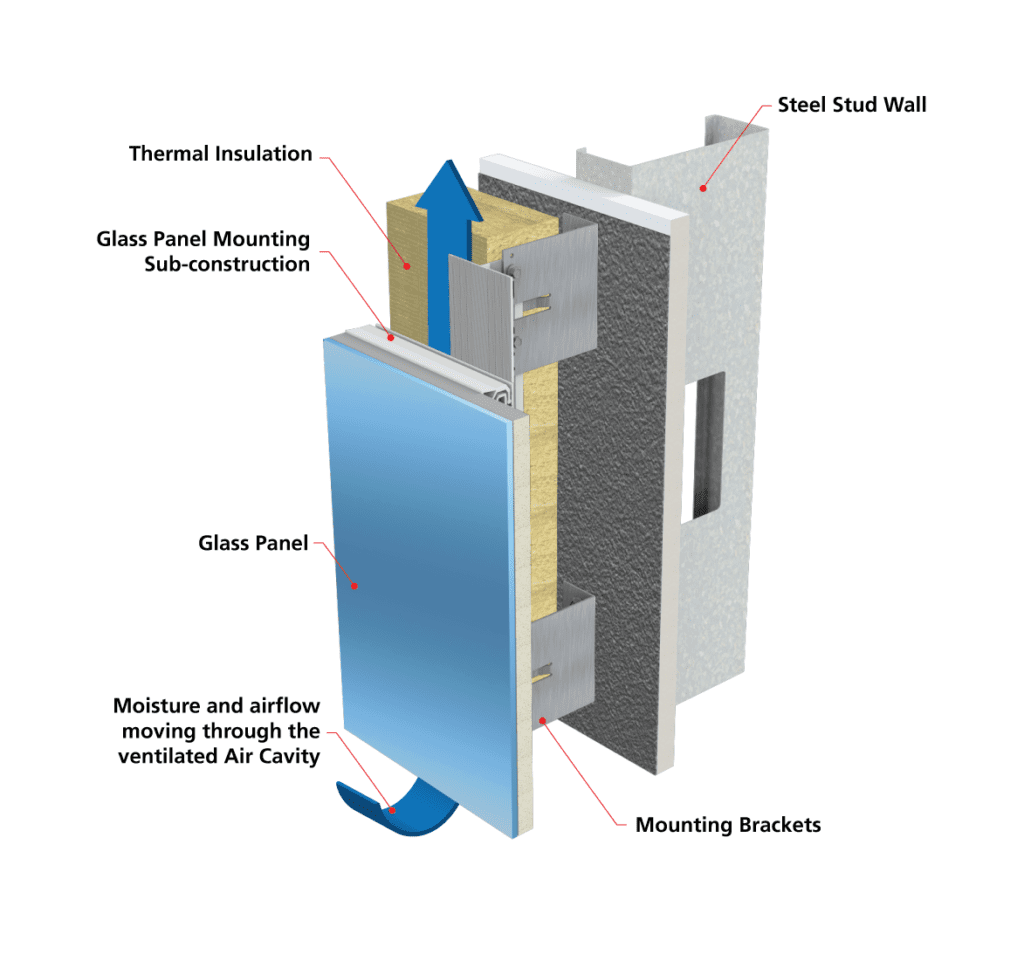

A complete Rainscreen System is comprised of several key structural components that work together to manage airflow and moisture effectively; these components include:

- Outer cladding material: The cladding is your building’s first line of defense. Depending on the building’s climate zone and local environment, you’ll want to choose the cladding type–fiber cement, metal panel, HPL, specialized render systems, etc.–based on the hazards present and the level of protection needed.

- Sub-construction: a structural system of brackets, rails, fasteners, and accessories that serves as the framework for the outer cladding material. This system absorbs both the wind and dead loads on the façade and is adjustable, accommodating uneven substrates and various façade cladding materials.

- Air gap or cavity: A ventilated space behind the cladding that helps manage moisture. A modern rainscreen system incorporates a larger air gap to promote drainage and drying of wall assemblies.

- Exterior insulation: This outer layer of insulation is capable of handling some moisture and drying without degrading or reducing its R-value. Depending on the thermal requirements and targets, this layer may be supplemented. Also, Energy codes require different degrees of exterior wall thermal performance.

- Air and water-resistive barrier (AWRB): This is attached directly to the building’s substrate and is the last line of defense against air leakage and moisture intrusion. Depending on the climate, the AWRB may be permeable or impermeable to water vapor.

- Venting profiles: There are several ventilation options available to help direct moisture away from the wall surfaces and to keep out pests.

Today’s rainscreens are nothing short of marvels of modern science. If you’re considering installing one, you’ll want to be aware of building codes that have impacted the implementation of these systems.

An Evolving Building Code

In recent years, we’ve seen a wave of new building codes. Many of these provide specifications that impact the implementation of a rainscreen system. Below are a couple of examples.

2021 Building Code Changes for Water-Resistive Barriers

Evolving building codes aim to create more resilient buildings. The 2021 International Building Code (IBC) and International Energy Conservation Code (IECC) made several changes to air and water-resistive barriers (WRBs) and air leakage, including:

- WRB compliance methods can include materials other than #15 felt.

- Registered design professionals or approved agencies must verify and commission air barriers when not testing

- Air barrier and air sealing details must be included on project drawings

- Air leakage testing requirements now include residential and non-residential buildings

- Performance verification is now required for buildings that are not tested

- Requirements to seal basements, slabs, and unvented crawlspaces at any penetration in the foundation or slab

Section BC 718.2.6

This New York City Building Code outlined the requirements for fireblocking within concealed spaces of exterior wall coverings, including the conditions and locations where fireblocking is required. Fireblocking must be installed within exterior wall assemblies that contain combustible components even when the wall assembly has previously passed the NFPA 285.

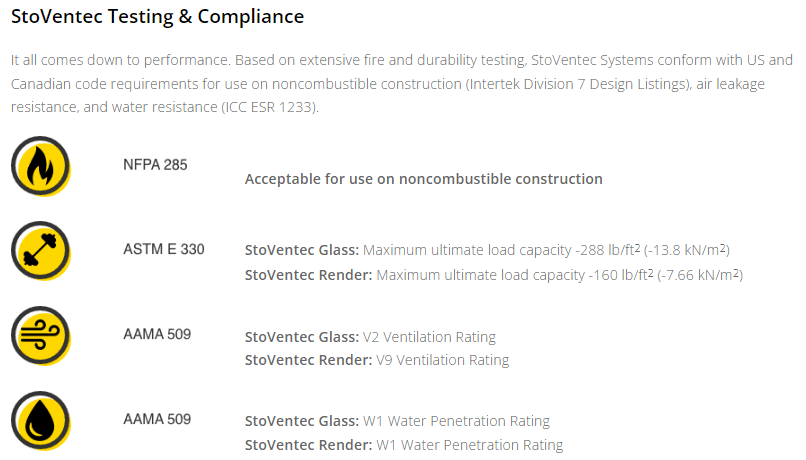

Assembly testing is becoming more and more critical in these new fire codes. Buildings must have a cohesive assembly designed to minimize fire risk, such as StoVentec, which is a fully tested assembly. Multiple wall claddings from various suppliers will be more heavily scrutinized in the years ahead.

The Importance of Proactive Moisture Management

Moisture accumulation within a building structure can cause problems such as water stains, ice damage, peeling paint, wood deterioration, mold, and mildew. Liquid water forms when water vapor in the building meets a surface with a temperature lower than the dew point of the air.

Whether or not the building is air and weather-tight can considerably affect thermal performance. A drafty, leaky building will undermine efforts to insulate, as heat will escape through the gaps that cause drafts and leaks.

For all these reasons and considering that water intrusion is a growing problem, the industry is pushing building owners to be more proactive in controlling moisture.

According to the E.P.A., a building’s design must include three features to control moisture. These features are:

- Controls bulk liquid water from snow, rain, etc.

- Stops a buildup of indoor humidity and water vapor migration by diffusion and airflow to minimize condensation and moisture absorption into cool surfaces and materials

- Made with moisture-resistant building materials

These features can be found in a modern rainscreen system like StoVentec® Rainscreen® Systems. Qualitative and quantitatively measured for rainscreen performance via AAMA 509 which tests wall assemblies against both static and dynamic air pressure with water spray simulating severe weather conditions and rates each system with classifications for water and ventilation.

An Innovative Solution that Meets Expectations and Standards

StoVentec® Rainscreen® Systems aim to exceed building code requirements by providing superior moisture management and resilience against severe weather, ensuring long-term building performance and durability.

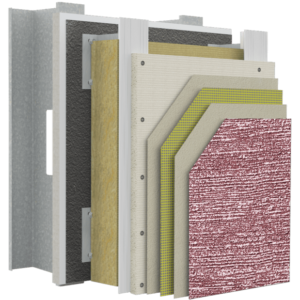

StoVentec Systems are a complete, fully-tested, and code-approved high-performance ventilated Rainscreen system. This includes a best-in-class air and water-resistive barrier, robust mineral wool continuous insulation, the most installer-friendly, adjustable sub-framing system available, and StoVentec Rainscreen cladding.

Benefits of StoVentec Rainscreen include:

- High-quality air and water-resistive barriers

- Non-combustible insulation

- Adjustable sub-framing

- Accommodates a wide variety of finishes and aesthetics

System Versus Component Approach

A system approach is when you specify a complete system from one manufacturer, and the components are all designed to work together. Sto offers a complete Rainscreen System with comprehensive testing, third-party code compliance evaluations, Florida Approvals and Miami-Dade NoAs. For example, Intertek Code Compliance Research Report 0454 evaluates the StoVentec Render and Masonry Veneer Facades systems for physical properties, weather resistance, wind resistance, surface burning characteristics, fire-resistance-rated construction, and use in Types I, II, III, and IV construction against the IBC, IRC, Florida Building Codes, and California Building Codes. The report also references and incorporates the independent evaluations dedicated specifically to the various Sto air and water-resistive barrier options, the all-important last line of defense in rainscreen wall systems. Further, the evaluation is built on a quality assurance program with independent random audits of production facilities which verifies the StoVentec system components are manufactured according to strict quality controls.

Other manufacturers only offer wall components, e.g., a single element in the system, such as cladding or insulation, leaving it up to architects and contractors to determine how these various bits and pieces should all come together. The component approach presents a range of challenges.

Challenges with the Component Approach

- Components aren’t always designed to work together, resulting in design collisions

- Many materials, players, and warranties often result in no party accepting full ownership of a problem

- Achieving aesthetic goals while meeting code requirements can strain a budget

- Misalignment of metal panels due to incompatibility/improper use of facade layer with sub-structure layer

Benefits of the System Approach

- Seamlessly connects design and construction

- Fewer products and subcontractors

- Improved constructability and project delivery

- One warranty – single supplier

- Compatibility of components

- Fully tested assemblies

- Weathertight transitions due to a single AWRB

When you select a complete Rainscreen System, you should receive details from the manufacturer defining:

- Air & water-resistive barrier

- Support structure, including attachment to the substrate

- Exterior insulation

- System ventilation

- Finish cladding

- Testing & warranty information

Real-World Applications and Compliance

It’s a harsh world out there, and StoVentec is up to the challenge. Here are some highlights from a couple of projects that demonstrate the possibilities.

Zislis Residence

Location: Manhattan Beach, California, USA

Building Type: Residential

Construction Type: New

When Michael Zislis, a successful entrepreneur, hotelier and restaurateur, was ready to build a home on the California coast for his young family, he wanted the exterior to be bold. When he learned about the enhanced aesthetic value and advanced performance properties of StoVentec Glass, Zislis was immediately intrigued.

When Michael Zislis, a successful entrepreneur, hotelier and restaurateur, was ready to build a home on the California coast for his young family, he wanted the exterior to be bold. When he learned about the enhanced aesthetic value and advanced performance properties of StoVentec Glass, Zislis was immediately intrigued.

With the home’s beachside location, StoVentec Glass was the ideal product. The multiple-sized panels of StoVentec Glass in varying shades of blue provide a unique appearance for a residential home. Because the product is tempered glass, it maintains reflective properties for a dazzling, durable exterior finish. The glass-faced panels integrate with thermal insulation and an air and moisture barrier to create one complete system that delivers stunning curb appeal and optimal performance characteristics.

Read the entire case study here.

Kalamazoo Justice Center

Location: Kalamazoo, Michigan USA

Building Type: Institutional

Construction Type: New

Located in downtown Kalamazoo, MI, the Kalamazoo Justice Center appeared to be a construction challenge. The building design featured a large glass expanse on the south side of the building, a curtainwall that would maximize natural lighting for the interior spaces. That same south-facing side of the building was to include a ground-floor pre-screening lobby. For the fascia of the one-story lobby space, the architects needed a product that visually extended the aesthetic of the modern glass curtainwall.

StoVentec Glass was the perfect fit since it is an insulated glass panel rainscreen system without visible hardware, so the fascia doesn’t feel like a framed curtainwall with hardware on the top, bottom, and sides. The fascia band on the lobby entrance area features nearly 700 square feet of StoVentec® Glass in an Ad Weiss Optiwhite™ Glass (9001W) color.

StoVentec® provides the striking visual effect the architects desired with the added bonus of delivering on performance and durability.

Read the entire case study here.

Want to see and read more real-world examples of how our robust Rainscreen System meets building codes and delivers superior protection for today’s buildings? Explore our full Project Gallery. From the functionality inside to the finish outside, this incredible system will help you meet your thermal and moisture goals while delivering a one-of-a-kind aesthetic.

Intelligent Solutions from an Industry Leader

Sto Corp. is the world’s leading innovator in claddings, air barriers, coatings, and restoration systems. By offering advanced rainscreens, such as StoVentec® Rainscreen® Systems, we are helping architects and builders achieve code compliance, enhance building longevity, and reduce maintenance costs.

For more information about StoVentec or Sto Corp., please visit www.stocorp.com or call (800) 221-2397.