Excellent patient care doesn’t happen by accident. It occurs as a result of attentiveness, precision, and expertise. No one is surprised they would expect the same from their construction projects.

Unfortunately, the construction industry must be more flexible, as it often struggles with variables beyond its control, such as weather and logistical challenges. However, there are ways to improve the quality and precision of the final product and make scheduling more predictable. One method is pre-fabrication.

Pre-Fabrication Explained

There are two types of prefab construction: modular and panel built. Sto’s prefabrication solution, Sto Panel Technology®, features prefabricated finished exterior wall panels. The StoPanel® system panels consist of cold-formed metal framing and all other components in a specified wall assembly, including glass mat sheathing, air and water-resistive barrier, continuous insulation (ci), sub-framing (if applicable), and the facade surface. StoPanel systems deliver what stand-alone components cannot: higher quality and dependability, fortified by third-party testing and code compliance.

The Benefits of Prefabrication

Prefabrication is a trend in healthcare for a reason. Actually, for many reasons. The benefits range from faster construction timelines to improved quality control and potential cost savings by minimizing on-site labor needs and waste. These are crucial factors in a sensitive environment like a hospital or other medical facility where continuous operations are critical.

These benefits sound great, but is there really a difference? Let’s examine some more closely, starting with faster construction timelines.

Construction with Fewer Disruptions

Prefabricated panels are manufactured in a controlled environment with all the various elements built in. As a result, there is greater quality and precision than traditional site-installed components. Because most of the construction is completed off-site, there will be less disturbance at your medical facility and reduced construction risks for workers and hospital operations.

Another point worth mentioning is that prefabricated panels are designed to be installed faster. On average, approximately 15,000 square feet of a building’s exterior surface can be installed per week or approximately 60,000 square feet/month when utilizing a Sto Panel Technology® system. This is just another way prefabrication enhances schedule certainty.

Potential Cost Savings

The truth is prefabricated panels aren’t the low-cost construction choice. However, they have the potential to unlock massive savings when it comes to a project’s schedule. As mentioned above, fewer workers are needed on-site, and the panels are designed to be installed faster. So, the man-hours for labor are dramatically reduced. Plus, prefabrication projects usually result in fewer RFI’s and change orders and less material waste. All of which could result in significant savings.

Engineered for a Precision Fit

Every prefabricated panel is fully engineered and includes connections for its unique configuration, position, and the structural frame to which it must attach. Typically, the panels are held about one inch off the edge of the slab and connected at every stud with custom-designed steel plates, angles, or other prefabricated connection components as required to carry the design loads and handle the expected movement of the building frame.

With traditional field-installed projects, you’re counting on the engineering of the individual components and that those components will be installed properly to perform well as a unit. With multiple contractors involved and the variability of weather, it’s easy to imagine where some inconsistencies can occur. Inconsistencies create weak spots in a building envelope that can and do affect performance.

Customization for Healthcare Aesthetics

Not only does Sto Panel Technology® deliver all the benefits of a prefabricated solution, it also offers design freedom. Architects and designers can choose from a wide variety of solutions to achieve a project’s desired aesthetic, such as 3D-printed facades, masonry veneers, resin-cast brick and wood, metal panels, fiber cement panels, and plaster finishes.

StoCreativ® Granite and StoSignature are two incredible finish options that can help healthcare organizations create the exact look they’re after. StoCreativ Granite is an acrylic-based interior and exterior wall finish formulated for durability and low maintenance that gives the appearance of cut or polished granite. StoSignature is a virtually endless blend of color, texture, profiles, and effects utilizing Sto products that create customizable finished surfaces.

Whether you need to meet facility aesthetic and operational requirements or want to accentuate your brand, Sto Panel Technology makes it possible.

Case Studies: Prefabrication in Healthcare

Prefabrication is a legitimate trend in healthcare, and now you know why. Check out our project gallery to see how Sto Panel Technology® is transforming sleepy medical buildings into architectural showpieces. We’ve highlighted a few of our favorite projects below if you want to take a quick peek.

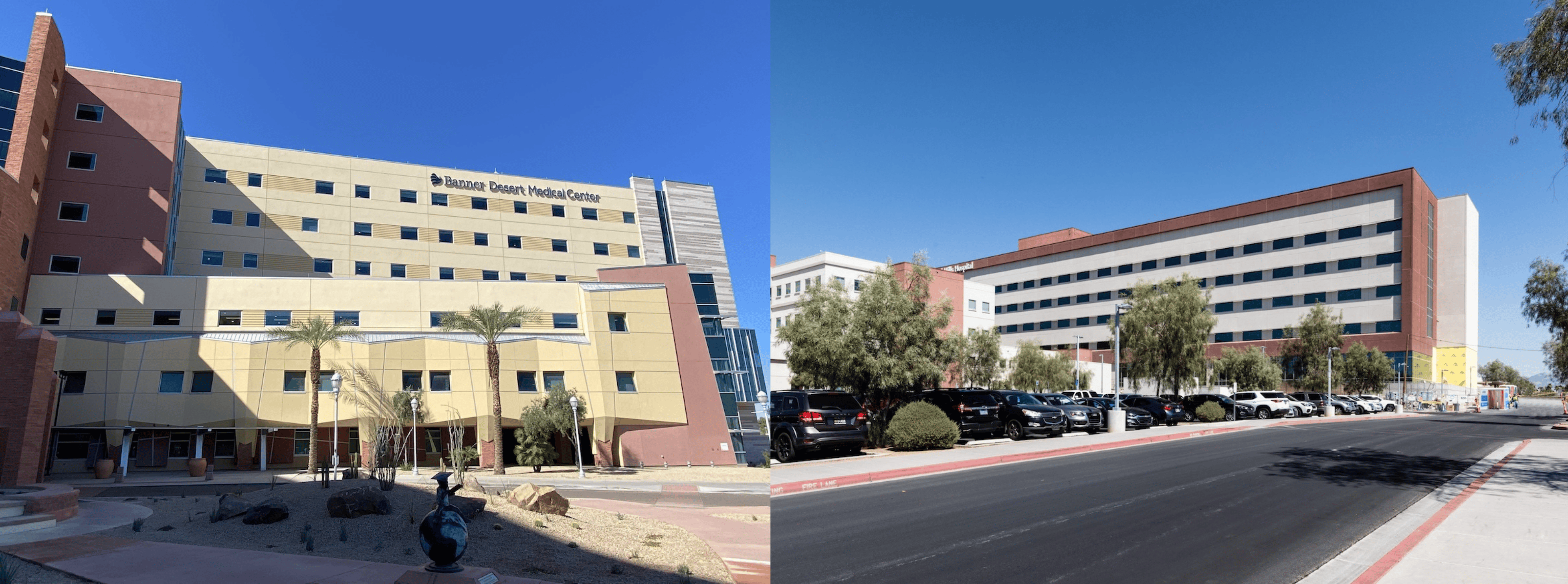

Banner Desert Medical Center

Location: Mesa, Arizona

Building Type: Healthcare

Construction Type: New

Banner Gateway Medical Center

Location: Gilbert, Arizona

Building Type: Healthcare

Construction Type: New

Learn how Sto Panel Technology was used to improve schedule and cost predictability.

Centennial Hills Hospital

Location: Las Vegas, Nevada

Building Type: Healthcare

Construction Type: New

Discover how Sto Panel Technology helped a GC meet an aggressive 40-day installation schedule.

Intelligent Solutions from an Industry Leader

Sto Corp. is the world’s leading innovator in claddings, air barriers, coatings, and restoration systems. So, it’s no surprise that we offer smart solutions like Sto Panel Technology® that are ideal for healthcare corporations seeking greater precision and predictability in their construction projects. We invite you to learn more about Sto Panel Technology and hope you will consider it for your next project.

For more information about Sto Panel Technology, visit our website, contact our support team, or call 800-221-2397.