Designing durable, energy-efficient, comfortable, and long-lasting homes and buildings requires a clear understanding and adequate installation of the different wall control layers, including the weather barriers (air, water, and vapor).

Together, weather barriers provide several vital functions to the building envelope:

- Air – Prevents excessive air infiltration

- Condensation – Resists condensation within the wall system

- Water – Resists liquid water penetration

- Energy Conservation – Resists thermal transfer through convection, conduction, and radiation

- Movement – Accommodates differential movement (caused by moisture, seasonal or daily temperature shifts, and structural movement)

Three Simple Differences Between the Four Building Envelope Restrictive Barriers

- Air Barrier vs. Vapor Barrier

-

- Air barriers restrict airflow (and the water attached) through a material. Air barriers can be either vapor permeable (allowing water vapor to pass through) or vapor impermeable

- Vapor barriers restrict the flow of water vapor (diffusion) through materials.

- Water Barrier vs. Vapor Barrier

- Moisture barriers may be either vapor permeable or vapor impermeable. Installing moisture barriers on the wall’s exterior stops bulk water from infiltrating the wall cavity while allowing water vapor to pass, helping to dry out the wall assembly if any incidental moisture should occur.

- Installing a vapor barrier on the frame’s interior, between the studs and drywall, stops vapor from the structure’s interior from infiltrating the wall system and condensing on the warm side of the insulation.

- Weather Barrier vs. Vapor Barrier

- Weather barriers prevent moisture, rain, and wind from passing through the building envelope. However, they also allow water within the wall system to dry quickly.

- Vapor barriers only limit water vapor (diffusion) flow through a material.

A Better Wall Solution to Conventional Vapor and Air Barriers

Traditionally, the tedious work of installing air and vapor barriers would cost builders time and expensive labor, with dire consequences if one system failed. Fortunately, Sto Corp.’s building envelope solutions include all five planes of control required for a high-quality building envelope system: air, vapor, thermal, durable water-shedding, and water-penetration control layers. Sto’s wall systems ensure energy-efficient, durable, safe, and sustainable structures with unique aesthetic appeal.

In addition, our StoGuard® liquid-applied air and moisture barrier products are a vital component of all Sto high-performance wall systems that help to seal the building envelope.

Air Barrier vs. Vapor Barrier Installations: What is the Difference?

Understanding the differences in air and vapor barriers can help ensure moisture-resistant, vapor-resistant, and airtight building envelopes – vital features of a durable, healthy, energy-efficient, and comfortable home or building.

What is an Air Barrier?

Air barriers include one or more products that form a continuous plane around a home or building to stop uncontrolled air, heat, and moisture flow in and out of the building envelope components. The building enclosure includes the above- and below-grade elements that physically separate the exterior and interior environments of the house or building.

The building enclosure includes three interactive components (an enclosure system and the interior and exterior environment) and five structural systems:

- Base floor

- Below-grade wall

- Above-grade wall

- Windows, skylights, and doors

- Roof

The Design of an Effective Air Barrier

An air barrier design manages air, moisture, heat, and solar radiation movement by effectively controlling the interactions between the building’s physical elements, the environment, and its occupants.

A quality air barrier system limits heat losses and gains through conduction, convection, and radiation:

- Thermal conduction happens when warmer molecules move towards colder molecules. The effective R-value of a wall system represents its resistance to conduction.

- Thermal convection happens when heat energy from a hotter area flows to a cooler place by moving fluids (usually gas and liquids).

- Thermal radiation transfers heat from warmer spaces to cooler spots by electromagnetic waves (mainly the Sun’s radiation).

High-quality air barriers should provide these four crucial components:

- Continuous over the entire structure’s building enclosure

- Impermeable to airflow

- The strength and stiffness to withstand forces acting on them during and following construction

- Structural durability (integrity) over the expected lifetime of the building or home

When tested according to ASTM E2178, an air barrier’s air permeance should not surpass 0.02 L/(s·m²) at a pressure difference of 75 Pa (0.004 cfm per square foot at a pressure difference of 1.56 lb per square foot). Air permeance represents the amount of air that flows through a material. In contrast, air leakage flows through gaps and holes.

Why Building Envelopes Need an Air Barrier

Air barriers control the indoor climate by preventing airflow between the exterior and interior of a building or home. In addition, air barriers stop air transported moisture to the interior of a wall cavity. Controlling air and moisture infiltration provides several significant benefits:

- Lowers building energy usage, which saves money and protects the environment

- Limits moisture in the wall cavity, preventing the growth of structurally damaging rot and mildew

- Improves occupant comfort and improves their productivity by stabilizing temperatures and eliminating drafts

- Improves indoor air quality by stopping the growth of unhealthy mold

Air Barrier Code Requirements

The International Building Code (IBC) and International Residential Code (IRC) provide code requirements for commercial and residential buildings.

Commercial Buildings

The 2021 IBC, Section C402.5.1, requires a continuous air barrier all around the building envelope for commercial structures (except climate zone 2B). Furthermore, builders can place air barriers outside or inside the building envelope, within the envelope assemblies, or any combination thereof. The air barrier must comply with Sections C492.5.1.2 and C402.5.1.1.

The IBCs apply to all structures and buildings that do not conform to the mandated provisions of the IRC.

Residential Buildings

The 2021 IRC (Table R402.4.1.1) requires installing a continuous air barrier in a building envelope and sealing breaks in its joints.

IRCs apply to detached one-and-two-family homes and townhouses no more than three levels above grade plane height. Additionally, they should have a separate means of egress with accessory structures no more than three stories above the grade plane in height.

What is a Vapor Barrier?

Vapor barriers limit or stop vapor diffusion, a process where moisture flows from a space of greater moisture concentration toward an area of lower concentration. It can also occur when moisture moves from a warmer to a cooler place within a building material, like insulation. Vapor barriers prevent diffusion, while vapor retarders only slow vapor diffusion.

The ASTM E96 desiccant method determines a building material’s ability to limit moisture from flowing through it, giving it a vapor retarder (barrier) class:

- Class I vapor barrier – 0.1 perms or less

- Class II vapor retarder – 0.1 < perm <1.0 perm

- Class III vapor retarder – 1.0 < perm <10 perm

Why Building Envelopes Need Vapor Barriers

Structural systems susceptible to direct contact with water require a vapor-resistant barrier. However, Sto Corp. recommends you contact your building inspection office for local guidance on using vapor barriers.

Builders often place vapor barriers on the interior wall and ceiling insulation to keep the warmer air inside a building from flowing towards the cool air within the wall assembly during winter.

Above-Grade Vapor Barriers

Building experts typically recommend installing vapor barriers on the wall’s more hot and moist side – the inner surface in cooler climates and the outer surface in humid, hotter climates. Examples of application of vapor barriers include:

- Placing polyethylene plastic vapor barriers between the insulation and interior wallboard in cold climates will help control moisture accumulation.

- Placing a vapor barrier in areas with high humidity, like bathrooms, will help manage condensation.

- An exterior vapor barrier in humid and hot climates can help keep outside humidity from infiltrating walls.

Below-Grade Vapor Barriers

- Placing a polyethylene moisture barrier over the exposed earth in crawl spaces will help manage moisture intrusion.

- Below-grade walls and floor slabs transmit ground moisture through concrete walls and slabs. Therefore, place a vapor barrier against the concrete surface to stop moisture infiltration before installing wood framing.

Code Requirements for Vapor Barriers

The need for a vapor barrier on a building’s exterior or interior depends on the climate zone. The 2021 International Building Code (IBC) 1404.3 and 2021 International Residential Code (IRC) R702.7 mandate Class I or II vapor retarders and barriers on the framed walls’ interiors in climate zones Marine 4 and 5,6,7, and 8. However, climate zones 1, 2, and 3 do not require vapor barriers and retarders.

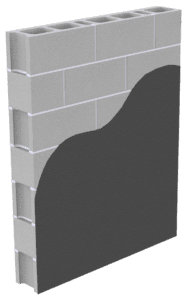

The Perfect Wall

Building Science Corporation first noted the idea of “The Perfect Wall” in 2010.

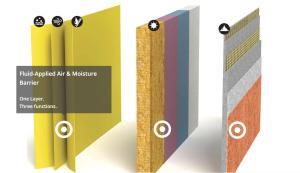

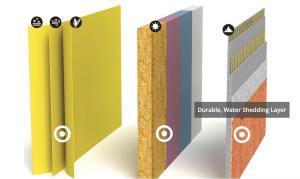

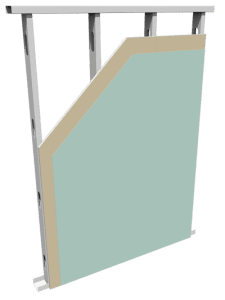

Sto Corp.’s building envelope solutions focus on performance and aesthetics. By including all five planes of control, Sto’s wall systems create energy-efficient, durable, safe, and sustainable structures with unique aesthetic appeal that will include: air, vapor, thermal, durable water-shedding, and water-penetration control layers.

- The Vapor Permeable or Impermeable Control Layer, per designer specification, controls the water vapor flow from areas of high to low pressure to minimize condensation.

- The Air Control Layer limits the uncontrolled air flow through the wall system to reduce condensation and energy loss.

- The Water Penetration Control Layer provides an inbound barrier of the cladding, flashed to the exterior, to stop liquid water from entering the wall cavity.

- The Thermal Control Layer provides insulation to lessen thermal bridging significantly.

- A Durable Water Shedding Layer offers a functional finish surface connected to a resilient lamina to protect against and divert water away from the wall.

StoGuard® Fluid-Applied Air and Water-resistive Barrier System

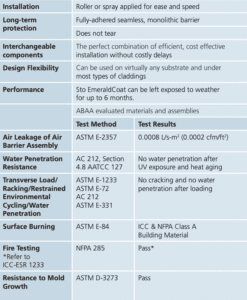

StoGuard® fluid-applied air and water-resistive barrier products provide a key component of all Sto high-performance wall systems, helping to seal the building envelope and providing several significant benefits:

- Wall system air leakage below 0.04 cfm/ft2 at 1.57 psf (0.2 L/s•m2 at 75Pa) when tested following ASTM E2357

- Potential savings of 40 percent in heating and cooling costs

- Low CO2 emissions

The StoGuard® System includes either vapor-permeable or impermeable fluid-applied membranes to accommodate all climate and wall designs and provide the first line of protection and seamless control over air and moisture infiltration, to improve building performance and occupant comfort.

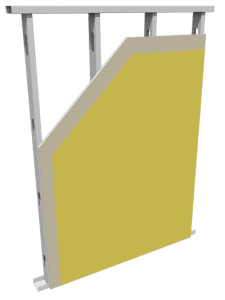

Water-based, fluid-applied, quick, and easy-to-install StoGuard air and water-resistive barriers form a fully-adhered, seamless monolithic moisture and air barrier on the exterior wall. They effectively protect against moisture infiltration and unwanted air movement for the lifetime of the building.

StoGuard® barriers do not tear and lose adhesion, like housewrap, which minimizes costly callbacks or even long-term system failure. In addition, characteristics of StoGuard® simplify the application process, installing in much less time compared to building wrap:

- You can apply StoGuard® liquid membranes with a roller or airless spray, which increases the speed of application on the wall while simplifying integration with other wall system components.

- StoGuard® systems include various interchangeable detail components that allow for continued protection on the wall regardless of the site conditions or complex design features.

Sto Fluid-Applied Air and Moisture Barriers

The StoGuard® System includes vapor-permeable or impermeable fluid-applied membranes, depending on climate and wall design.

Sto Gold Coat®

Vapor-permeable, flexible fluid-applied membrane designed for installation on most commonly used substrates. It can be used as part of StoTherm, StoPowerwall, StoQuik and StoVentec wall systems, and is suitable for use behind most exterior claddings including rainscreen, metal, wood, stone, brick, and masonry.

Sto AirSeal®

Builders can use vapor permeable, roller, and spray fluid applied Sto AirSeal® behind StoVentec™ RainScreen®, StoTherm® ci, StoPowerwall®, StoQuik® Silver and above-grade walls behind claddings (e.g., brick stucco, metal panels, cement board). It applies over prepared vertical above-grade wall substrates like concrete masonry, concrete, plywood, OSB sheathing, and glass mat gypsum.

Sto VaporSeal™

Class 1 Vapor Retarder designed for spray or roller installation to most commonly used substrates. It can be used as part of StoTherm, StoPowerwall, StoQuik and StoVentec wall systems, and is suitable for use behind most exterior claddings including rainscreen, metal, wood, stone, brick, and masonry. Sto VaporSeal® features 500% elongation and meets requirements of ASTM C1305.

Sto’s detail components include:

StoGuard RediCorner – Transition Membrane

Sto RapidGuard® is a single-component, moisture-cured, damp surface tolerant air and water-resistive barrier component and flexible flashing material. It is the preferred StoGuard Detail Component for complex shapes such as penetrations and complex rough openings.

StoGuard Fabric – Sheathing Joint Treatments

StoGuard® Fabric 4″ is a non-woven cloth reinforcement. As part of the StoGuard® assembly, you can use it with either Sto Gold Coat®, StoGuard® VaporSeal®, or Sto AirSeal to treat sheathing joints, rough openings, and inside and outside corners.

StoGuard® Conformable Membrane is a self-adhered membrane featuring an aggressive no-primer adhesive and a facing membrane that provides 1470% elongation. Minimum installation temperature is 20°F. The high-elongation facer membrane readily conforms to complex shapes found on the building enclosure.

Why Choose Sto Products for Air and Vapor Barrier Installations

Sto Systems provides architects, contractors, and developers with a quick, straightforward-to-install, tested, and cutting-edge, high-performance building envelope. Sto’s high-performance wall systems and StoGuard® air and water-resistive barrier system deliver on all performance needs, including air and vapor barriers, by saving money and time and reducing labor, risk, and complexity compared to systems with multiple components.

Independent testing shows that Sto systems meet water infiltration and ventilation performance specifications, impact resistance, wind load resistance, water resistance, accelerated weathering, and flame spread.

For more on the differences between an air barrier and vapor barrier installation and how to best achieve high-performance building envelope systems with Sto products, download our comprehensive guide on engineered building enclosures or contact us today!