Buildings are imperfect. Whether it’s new construction or an existing building, they have crooked exterior walls/substrates or are smothered in layers of coating from previous renovations. While new buildings have the potential to have straight exterior walls, the requirements of those walls in the future are uncertain. How is the future uncertain? There are shifting weather patterns and more extreme weather events that buildings must endure. Building codes also evolve. New design trends can impact exterior walls as well. These things can force cladding changes that must be installed over the sub-construction. And that’s a few reasons why an adjustable sub-construction is a smart decision. We’ll get to the others, but first, let’s talk about what this future-friendly system looks like.

How Does an Adjustable Sub-Construction System Work

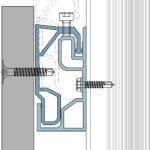

Imagine a comprehensive system of brackets, rails, fasteners, and other accessories that work together to create a framing system that can be adjusted as needed to make a perfectly flat, square surface to install the façade cladding. At Sto, that system is StoVentro™. Part of our innovative StoVentec®Rainscreen® System, StoVentro absorbs both the wind loads and dead loads present on the facade. Alongside structural suitability, the design of the sub-construction incorporates corrosion resistance and a reduction in thermal bridging while also being quick and easy to install.

Imagine a comprehensive system of brackets, rails, fasteners, and other accessories that work together to create a framing system that can be adjusted as needed to make a perfectly flat, square surface to install the façade cladding. At Sto, that system is StoVentro™. Part of our innovative StoVentec®Rainscreen® System, StoVentro absorbs both the wind loads and dead loads present on the facade. Alongside structural suitability, the design of the sub-construction incorporates corrosion resistance and a reduction in thermal bridging while also being quick and easy to install.

Installation Made Simple

The good news for general contractors: StoVentro is easy to install in three straightforward steps.

Align Brackets

First, you’ll want to align brackets to proper (loading design-specific) horizontal and vertical spacings. Anchor to structure with substrate-appropriate fasteners.

Align Vertical Profiles (T’s and L’s)

If cutting the rails, be sure to deburr the edges. Use clamps to temporarily secure vertical rails to the brackets. Install the first and last profiles on each façade plane, then use a horizontal reference line to align the remaining profiles. Or use a laser or spirit level to align the exterior axes (front flanges of the T and L profiles).

Fasten Profiles

Use StoVentro sub-construction screws to fasten the profiles to the brackets. Utilize oblong fastener slots on the small brackets for sliding point fastening and the circular holes on the large brackets for fixed point fastening. This allows the profiles to thermally expand and contract.

Now that the sub-construction is in (wow, that was easy!), let’s talk about the cladding.

Adaptable to Different Material Types and Thicknesses

We’ve mentioned how an adjustable sub-construction can turn imperfect walls into perfectly square walls. But what about the cladding that will, inevitably, sit atop this sub-construction? That system of brackets, rails, and fasteners all make for a very adaptable, flexible system. That means no matter what external cladding materials you use and how thick they may be, the sub-construction can accommodate it. That’s one of the primary purposes of the system. Who knows what future building design will look like? With an adaptable sub-construction system, you will be ready for what’s next.

We’ve mentioned how an adjustable sub-construction can turn imperfect walls into perfectly square walls. But what about the cladding that will, inevitably, sit atop this sub-construction? That system of brackets, rails, and fasteners all make for a very adaptable, flexible system. That means no matter what external cladding materials you use and how thick they may be, the sub-construction can accommodate it. That’s one of the primary purposes of the system. Who knows what future building design will look like? With an adaptable sub-construction system, you will be ready for what’s next.

Built for Design Flexibility and Originality

If you are building over an old wall without a sub-construction system, your cladding options are limited. But with a modern sub-construction system, the possibilities are unlimited. The StoVentro system serves as the foundation for all StoVentec systems, allowing for the use of glass, a wide variety of Sto architectural finishes, and masonry veneer. It is so adaptable that you can use virtually any cladding system, even one made by other manufacturers. The design possibilities are endless!

Improved Building Performance

We’ve covered several benefits of a sub-construction system, but there are a few significant benefits we haven’t yet covered. One critical benefit to building performance is that the StoVentro system allows for ventilation and drainage. Another advantage of an adjustable sub-construction system is that it can improve the thermal and acoustic performance of the building envelope. By incorporating an adjustable system, you can address any issues quickly and efficiently, minimizing “downtime” and ensuring consistent, maximum performance. Plus, the combination of the rainscreen and cladding systems used on top of the StoVentro system can help maximize energy efficiency by making space for exterior thermal insulation.

A Leader in Innovative, Sustainable Building Solutions

At Sto, we are focused on addressing the evolving needs of modern construction. We are committed to creating solutions that perform at the highest level and are sustainable. The StoVentro system is one of our most innovative systems. It is an easily installed, adjustable sub-construction that can compensate for existing walls or substrates that aren’t straight and make using multiple materials on the facade easier. To learn more about StoVentro, visit https://www.stocorp.com/sto_systems/stoventro/. Ready to explore designs? Download our design guide or our installation guide.