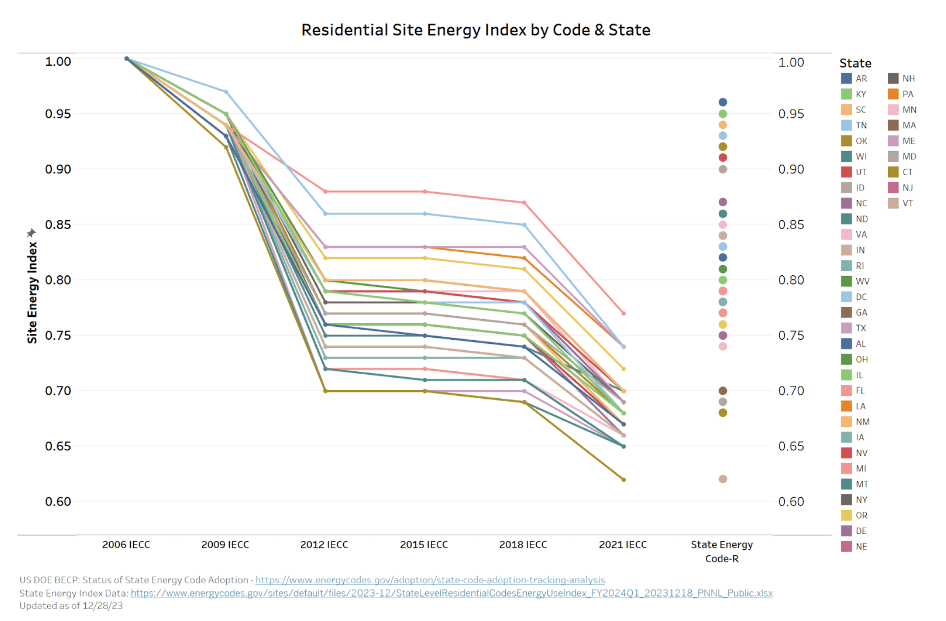

Advancements in building energy codes strive to enhance a structure’s energy efficiency, with the ultimate goal of obtaining net zero energy building (NZB) status.

In 2000, the International Code Council (ICC) developed the International Energy Conservation Code (IECC). The purpose of the IECC is to establish the minimum design and construction energy efficiency requirements for renovated and new buildings. Between 2006 and 2021, the IECC increased its efficiency requirements by about 40 percent – an average of 8 percent per cycle.

The IECC uses ASHRAE 90.1 (the minimum requirements for energy-efficient buildings, except for low-rise residential buildings) as the ICC referenced standard for energy-efficiency. The ICC Referenced Standards Guide is an industry agreement of the level of performance in the designing, manufacturing, testing, and installing of materials, products, or assemblies. ICC Referenced Standards only become law once a jurisdiction references them in an I-Code.

Local and State Authorities Mandate Regional Building Codes

Local and state jurisdictions set energy building codes for their regions; however, most refer to and adopt the codes set by the commercial and residential IECC. States and municipalities depend on the IECC because of the cost and complexity of developing building codes and standards. All states and the District of Columbia have adopted the IECC, and adapted them to fit their local construction practices, climate, and geography.

https://www.energycodes.gov/infographics

IECC Commercial and Residential Air Barrier Building Codes

The ICC updates the IECC every three years. The newest version was published in 2021 and includes air barrier standards for commercial and residential buildings.

Testing and Performance Requirements for Air Barriers

Air barrier materials must achieve air permeance (air that permeates a material) no more than 0.02 L/(s·m²) at a pressure difference of 75 Pa (0.004 cfm/ft2 at a pressure difference of 1.56 lb/ft2 ) when tested, following ASTM E2178.

Air Barrier Application to Commercial Buildings

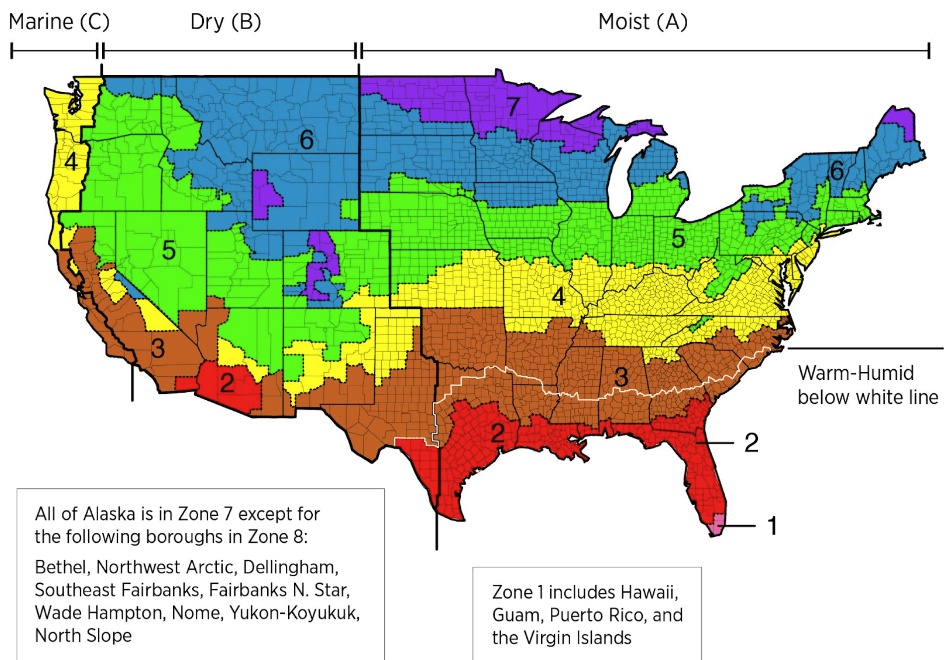

Section C402.5.1 of the 2021 IBC states, “A continuous air barrier shall be provided through the building thermal envelope. The continuous air barriers shall be located on the inside or outside of the building thermal envelope, located within the assemblies composing the building thermal envelope, or any combination thereof.” There is one exception: air barriers are not required in buildings located in Climate Zone 2B.

https://basc.pnnl.gov/images/iecc-climate-zone-map

Additionally, the air barrier must comply with Sections C402.5.1.1 and C402.5.1.2:

Section 402.5.1.1

The continuous air barrier shall be constructed to comply with the following:

- The air barrier shall be continuous for all assemblies that are the thermal envelope of the building and across the joints and assemblies.

- Air barrier joints and seams shall be sealed, including sealing transitions in places and changes in materials. The joints and seals shall be securely installed in or on the joint for its entire length so as not to dislodge, loose or otherwise impair it’s ability to resist positive and negative pressure from wind, stack effect and mechanical ventilation.

- Penetrations of the air barrier shall be caulked, gasket or otherwise sealed in a manner compatible with the construction materials and location. Sealing shall allow for expansion, contraction and mechanical vibration. Joints and seams associated with penetrations shall be sealed in the same manner or taped. Sealing materials shall be securely installed around the penetration so as not to dislodge, loose or otherwise impair the penetrations’ ability to resist positive and negative pressure from wind, stack effect and mechanical ventilation. Sealing of concealed fire sprinklers, where required, shall be in a manner that is recommended by the manufacturer. Caulking or other adhesive sealants shall not be used to fill voids between fire sprinkler cover plates and walls or ceilings.

- Recessed lighting fixtures shall comply with Section C402.5.10. Where similar objects are installed that penetrate the air barrier, provisions shall be made to maintain the integrity of the air barrier.

Section 402.5.1.2

A continuous air barrier for the opaque building envelope shall comply with the following:

- Buildings or portions of buildings, including Group R and I occupancies, shall meet the provisions of Sections C402.5.2.

Exception: Buildings in Climate Zones 2B, 3C and 5C

- Buildings or portions of buildings other than Group R and I occupancies shall meet the provisions of Section C402.5.3

Exceptions: 1. Buildings in Climate Zones 2B, 3B, 3C, and 5C. 2. Buildings larger than 5000 square feet (464.5 m2) floor area in Climate Zones 0B, 1, 2A, 4B, and 4C. 3. Buildings between 5,000 square feet (464.5 m2) and 50,000 square feet (4645 m2) floor area in Climate Zones OA, 3A and 5B.

- Buildings or portions of buildings that do not complete air barrier testing shall meet the provisions of Section C402.5.1.3 or C402.5.1.4 in addition to Section C402.5.1.5.

Residential Structures

The 2021 IRC (Table R402.4.1.1) mandates sealing breaks for joints in the air barrier and a continuous air barrier in the building envelope. IRCs apply to detached one-and-two-family townhouses and dwellings not exceeding three stories above grade plane height. They must also provide a separate means of egress with accessory structures not exceeding three stories above grade in height.

2024 IECC Proposed Changes

Development of the 2024 national model energy codes by the ICC is well on its way. In previous years, the final decisions rested on the votes of government officials. For 2024, two consensus committees (commercial and residential) that represent various stakeholders, will make the decisions.

The 2024 IECC proposed changes aim to improve overall energy performance compared to the 2021 IECC, with 250 + proposed changes to the commercial energy code and 200 proposed changes to the residential energy code.

The Importance of Certification and Compliance

The current energy codes take cost-effectiveness into account in the latest building science and technology. States and municipalities that routinely adopt the updated codes, along with contractors and architects complying with the codes, can achieve the cost, climate, health, and safety benefits of the IECC International Codes (I-Codes).

The I-Codes address air barriers, insulation, HVAC equipment, windows, and other components that enhance occupant health and comfort, lower emissions, and ensure durability. The U.S. Department of Energy predicts that between 2010 and 2040, building energy codes will save the U.S. $138 billion, reduce CO2 emissions by 900 MMT, and lower energy use by 13.5 quads.

StoGuard® Family of Air and Water-Resistive Barriers for Code Compliance

Sto’s complete system approach offers architects and contractors a one-source solution for the building envelope, including the StoGuard family of air and water-resistive barrier products. The family of products includes a variety of air and water-resistive barrier membranes and StoGuard detail component accessories that can be selected based on the use case, application method, permeability, and substrate.

Thoroughly tested and code compliant against the stringent green construction codes, StoGuard® systems are the superior choice for design professionals who want to apply a single-source, continuous, fully compatible air and water-resistive barrier system to the exterior walls on multi-cladding buildings.

StoGuard® systems comply with the following building codes:

- International Building Code

- International Residential Code

- International Energy Conservation Code

- Los Angeles Building Code

- International Green Construction Code

- CALGreen Title 24

- ICC 700 National Green Building Standard

- You can find additional codes and standards within ICC-ESR 1233

StoGuard® Systems seamlessly control moisture and air infiltration, which enhances building performance and occupant comfort. The low-VOC StoGuard® family of products includes fully compatible accessories usable with StoGuard® fluid-applied membranes to produce a StoGuard® Air and Water-Resistive Barrier assembly.

Fluid-Applied Air and Water-Resistive Barriers

Sto Gold Coat®

Sto Gold Coat® is a versatile liquid-applied membrane with built-in antifreeze properties, crafted for application on a variety of commonly used surfaces. It is compatible with StoTherm, StoPowerwall, StoQuik, and StoVentec wall systems, and is appropriate for placement behind a range of exterior claddings such as rainscreen, metal, wood, stone, brick, and masonry.

Sto AirSeal®

Sto AirSeal® is a versatile, liquid-applied membrane specifically crafted for medium and high build applications. It is a compatible component of StoTherm, StoPowerwall, StoQuik, and StoVentec wall systems, and is well-suited for application behind a wide range of exterior claddings, including rainscreen, metal, wood, stone, brick, and masonry.

Featuring an impressive 500% elongation and meeting ASTM C1305 Low Temperature Crack Bridging requirements, Sto AirSeal® exhibits exceptional flexibility. Its unique rheology is optimized for high-build installations.

Sto VaporSeal®

Sto VaporSeal® is a Class 1 Vapor Retarder, crafted for application through spray or roller methods on a variety of commonly used surfaces. It is a compatible component of StoTherm, StoPowerwall, StoQuik, and StoVentec wall systems, and is well-suited for installation behind a diverse range of exterior claddings, such as rainscreen, metal, wood, stone, brick, and masonry. With a 500% elongation capability, Sto VaporSeal® meets the stringent requirements of ASTM C1305.

Sto ExtraSeal®

Sto ExtraSeal® is a Portland cement based, trowel applied air barrier. It is specifically designed for use in stucco systems directly applied to poured concrete and masonry substrates.

StoGuard Detail Components

Sto RapidGuard®

Sto RapidGuard® is a single-component, moisture-cured air and water-resistive barrier, along with being a flexible flashing material. It is the recommended StoGuard Detail Component for intricate shapes, including penetrations and complex rough openings.

StoGuard® Conformable Membrane

StoGuard Conformable Membrane is a self-adhesive membrane with a robust no-primer adhesive and a facing membrane that offers an impressive 1470% elongation. It can be installed at a minimum temperature of 20°F. The highly flexible facing membrane easily conforms to intricate shapes commonly found on the building enclosure.

StoGuard® Fabric

StoGuard® Fabric is a durable reinforcement intended for saturation with Sto Gold Coat®, Sto AirSeal®, or Sto VaporSeal® to create a waterproof and flexible flashing material, as well as to treat sheathing joints.

Sto Gold Fill®

Sto Gold Fill® is a pre-mixed product applied with a trowel. StoGuard Mesh is incorporated into StoGuard Fill, forming a waterproof composite material. Combined, they are suitable for treating sheathing joints and providing flashing for rough openings.

StoGuard® Mesh

StoGuard® Mesh is a glass fiber self-adhesive mesh for use with Sto Gold Fill®, available in 4.25- and 9.5-inch widths.

Sto Detail Mesh

Sto Detail Mesh is a coated glass fiber mesh and can be used with Sto Gold Fill. Together they can be used to treat sheathing joints and flash rough openings.

For more on air barrier and building code changes visit our website (link to https://www.stocorp.com/air-water-resistive-barriers/), or contact an air and water barrier expert at Sto® today at (800) 221-2397.

You can also use energy code compliance software tools, like REScheck and COMcheck, for residential and commercial buildings to determine if your building’s design meets energy code mandates.