Since prehistoric times, humans have sought to protect our homes and gathering places better. Comfort was the primary driver, so our early ancestors created thermal insulation with readily available materials such as animal fur and plants. Over time, earth, mud and stone were used. Eventually, the Greeks would invent insulation similar to what we use today.

A significant development in the evolution of building protection occurred in the 19th century during the Industrial Revolution. Construction became recognized as separate from design. Physics, mathematics, chemistry and thermodynamics were all being developed and applied to create building science as a discipline. At the same time, architecture, engineering and construction were all becoming more defined. Suddenly building protection was about much more than insulation.

A Highrise Changes the Game

Often referred to as the world’s first skyscraper, the Home Insurance Building in Chicago was erected in 1885 and stood until 1931. The building was designed by William Le Baron Jenney and weighed as much as one-third of typical masonry buildings, which concerned city officials.

According to History.com, “His revolutionary design utilized an inner skeleton of vertical columns and horizontal beams made out of steel. This was in stark contrast to earlier structures, which were supported by heavy masonry walls. Steel was not only lighter than brick, but it could carry more weight. With this new method of construction, lighter masonry walls could be “hung,” a bit like curtains, from the steel frame. As a result, the walls of the building didn’t have to be as thick, and the structure could be much higher without collapsing under its own weight. Buildings with this type of frame could also have more windows, as the steel frame supported the building’s weight and the stone or brick exterior merely acted as a “skin” to protect against weather.”

The emergence of building science led to this project, marking the building envelope’s beginning.

Science Fills in the Insulation Gaps

While insulation had improved since the days of mud and fur, it was still built on the idea that the Greeks had developed hundreds of years before. Fortunately, science and technology would also benefit this necessary building material.

One of the most significant developments was the widespread use of fiberglass insulation in the 1930s. More recently, it was the increased use of polyurethane foams for filling the cavities between walls. These more advanced products helped our homes and buildings achieve greater comfort while improving energy efficiency.

Insulation That Achieves More with Less

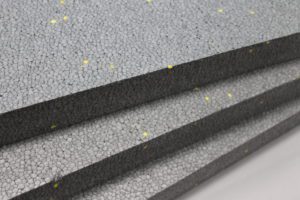

At Sto Corp., sustainable construction is ingrained in our company’s DNA. This commitment guides us in our decision-making and product development. Our GPS insulation is the perfect example of our continuous pursuit of greener products, representing the future of insulation. GPS (graphite polystyrene) is a rigid, graphite-enhanced, 100% closed-cell expanded polystyrene insulation board. We use graphite because it is the most stable form of carbon – safe and chemically inert. Plus, it reduces thermal conductivity and increases the R-value by as much as 25%.

The primary difference between GPS and traditional insulation products is that GPS insulating boards are thinner. In fact, they are up to 20% thinner than other rigid insulation boards. That means less material is required to achieve the same R-value. And the product itself is recyclable, making it more environmentally friendly.

For additional information on the various types of insulation offered by Sto and to compare the features and benefits of each, visit our insulation comparison web page.

Advancement in Material Science and Engineering

With each passing year, breakthroughs in materials science and technology push the boundaries of what’s possible, leading to stronger, more sustainable and more resilient buildings. Nanotechnology is enhancing construction materials with improved strength, durability and thermal conductivity. The result is layer upon layer of building protection that is more advanced than ever.

Smarter, Longer-Lasting Coatings and Finishes

At Sto®, we have a long, proven history of developing innovative coating technologies. Now, we’ve developed a group of architectural coatings that provide more value by providing more functionality. Sto Intelligent Technology + Design™ (iQ Technology™) interweaves innovation with design to offer high-performance coatings with unique attributes based on biomimicry principles that enhance aesthetics and improve occupant comfort.

The functionality behind StoColor® Dryonic® and StoColor® Lotusan® is inspired by nature and designed to address the true needs of a building, not just the standards. Because these coatings deliver improved function through optimized product attributes, property owners will realize greater durability and lower lifecycle costs. This technology is also available in StoLit Lotusan, a textured finish that captures the look of traditional plaster, brick, or limestone with self-cleaning properties.

State-of-the-Art Rainscreens

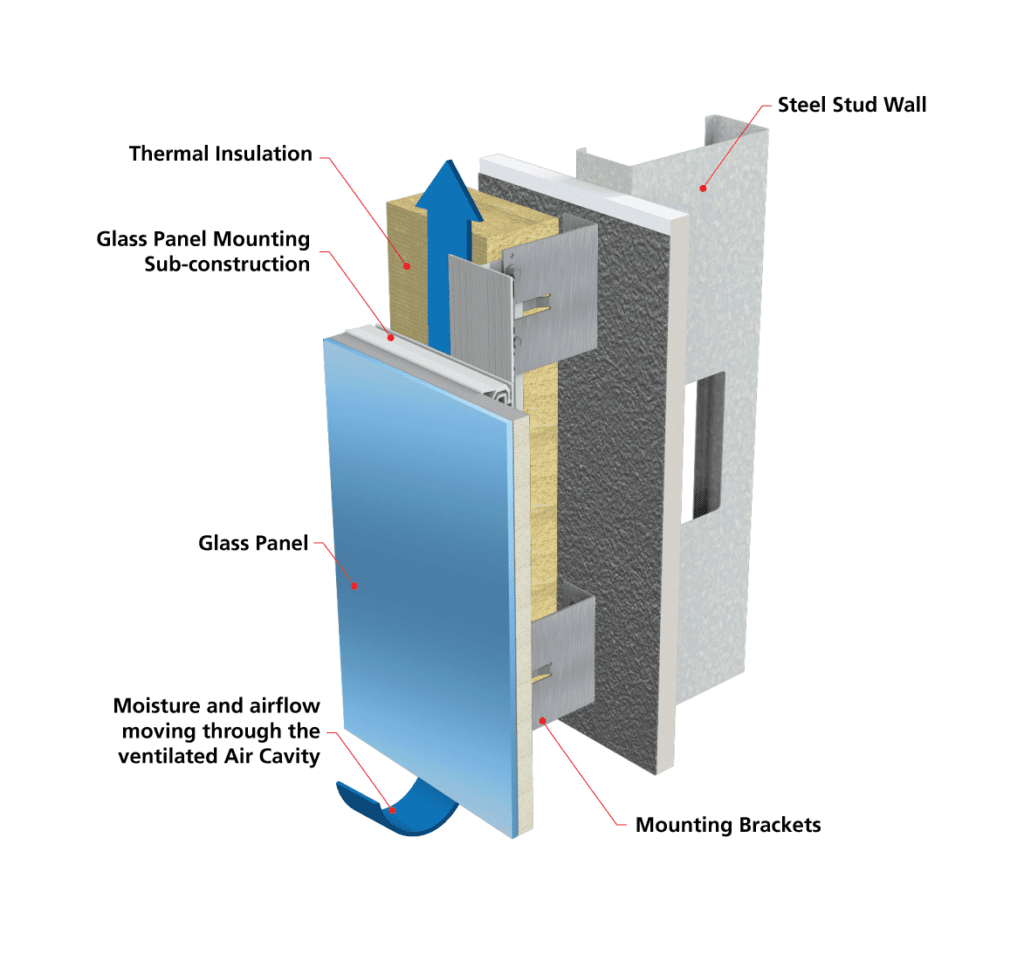

Today’s rainscreens are nothing short of marvels of modern science. They are comprised of several key structural components that work together to manage airflow and moisture effectively; these components include:

- Outer cladding material: The cladding is your building’s first line of defense. Depending on the building’s climate zone and local environment, you’ll want to choose the cladding type–fiber cement, metal panel, HPL, specialized render systems, etc.–based on the hazards present and the level of protection needed.

- Air gap or cavity: A ventilated space behind the cladding that helps manage moisture. A modern rainscreen system incorporates a larger air gap to promote drainage and drying of wall assemblies.

- Air and water-resistive barrier (AWRB): This is attached directly to the building’s frame and is the last line of defense against air leakage and moisture intrusion. The AWRB may be permeable or impermeable to water vapor, depending on the climate.

- Exterior Insulation: This outer layer of insulation is capable of handling some moisture and drying without degrading or reducing its R-value. Depending on the building owner’s thermal requirements and targets, this layer may be supplemented. Also, Energy codes require different degrees of exterior wall thermal performance.

- Venting Profiles: There are several ventilation options available to help direct moisture away from the wall surfaces and to keep out pests.

The Perfect Wall

Technology advancements have also allowed modern construction to achieve the perfect wall, a complete, engineered system that performs better and saves money over the long term. The perfect wall contains all four building enclosure control layers:

- Air Control Layer – To limit the uncontrolled flow of air through the wall assembly, reducing condensation and energy loss.

- Water Penetration Control Layer – Barrier inbound of the cladding, flashed to the exterior, designed and installed to prevent liquid water from entering the wall cavity.

- Vapor Control Layer – Vapor permeable or impermeable per designer specification, controls the flow of water vapor from areas of high to low pressure, minimizing condensation.

- Thermal Control Layer – Insulation to significantly reduce thermal bridging.

Sto offers a wide range of wall systems, from prefabricated wall panels to EIFS with drainage, plus many more. From superior performance and sustainability to inspired aesthetics, your perfect wall is just a few clicks away with the Sto® Wall Selector.

Material Science: The Next Generation of Building Products

The pace at which material science is advancing is ever-accelerating. Lightweight cladding is the next big thing for the construction industry. With lightweight cladding, it’s no longer necessary to use heavy materials such as masonry, concrete, metal panels, precast, porcelain, or even fiber cement to achieve the look of brick, wood, concrete, or metal. The benefits of lightweight cladding include:

- Smaller carbon footprint

- On-the-wall energy performance

- Authentic aesthetics

- Simpler and safer for construction crews

- Lower energy bills

- Near limitless design freedom for architects

StoCast, one of our most exciting and popular new products, is an example of this innovative new cladding. StoCast Wood is a resin cast product that can be applied to a variety of Sto wall systems to deliver a real wood aesthetic. StoCast Brick replicates the look of traditional brick and is available in 30 standard bricks or project-specific colors, patterns and textures.

The Future of Building Protection is Here

Building protection has come a long way since the days of mud and fur. At Sto, we are proud to be a leader in innovative, sustainable building solutions that enhance aesthetic value, durability and energy efficiency, addressing the evolving needs of modern construction. We invite you to learn more about our rainscreens, coatings and finishes. For more information about Sto Corp. and our building envelope solutions, visit Stocorp.com.