Longer wildfire seasons as well as stricter standards are prompting builders and architects to use non-combustible construction methods and materials, like mineral wool continuous insulation (CI).

The National Interagency Fire Center reported 68,988 wildfires in 2022 (consuming 7,577,183 acres), compared to 58,985 wildfires in 2021 (consuming 7,125,643 acres). Many scientists blame the increased wildfires on higher global temperatures, drier forests, and early snow melts due to climate change. Protecting a building and its occupants from dangerous fires requires non-combustible construction.

Maggie’s Center in London utilized StoTherm® Mineral ci, made with non-combustible mineral wool insulation for their new, field-built healthcare center.

What is Non-Combustible Construction?

Non-combustible construction includes non-combustible materials, like mineral wool insulation, incorporated into the building’s structural elements, including structural framing, roof, floor construction, supporting features, and wall systems.

A building’s structural elements and fire-resistance ratings determine its construction type and classification, including non-combustible construction.

An Ideal Solution to Non-Combustible Wall Construction

StoTherm® ci Mineral creates non-combustible wall systems for residential, commercial, industrial, and institutional structures. StoTherm® ci Mineral incorporates non-combustible, mineral wool exterior CI into its high-performing, durable, and sustainable cladding system that passes NFPA testing.

Non-Combustible Construction Types and Classifications

Three governing bodies provide building construction types and classifications:

1. The National Fire Protection Association (NFPA) defines construction types and classifications in the NFPA 220, Standard on Types of Building Construction

2. The International Building Code (IBC) defines construction types and classifications in Chapter 6, Types of Construction.

3. The Insurance Services Office (ISO) defines construction types and classifications on its website’s Construction Briefs page.

Type I and II – Fire Resistive, Non-Combustible Construction

- NFPA: Firewalls, structural elements, floors, walls, arches, and roofs with approved non-combustible or limited combustible materials

- IBC: Construction types with non-combustible building elements

- ISO Class 6 (Fire Resistive): The non-combustible or masonry exterior bearing walls and load-bearing portions of exterior walls. However, exterior nonbearing walls and wall panels may be combustible, slow-burning, or with no fire-resistance rating.

- ISO Class 5 (Modified Fire Resistive): Building construction consists of fire-resistive materials like masonry and protected steel materials not less than 4 inches thick

- ISO Class 4 (Masonry Non-combustible): Masonry non-combustible construction consists of concrete blocks or reinforced masonry combined with steel framing

- ISO Class 3 (Non-combustible): Buildings with non-combustible or slow-burning exterior walls, roofs, and floors

Type III – Ordinary

- NFPA: Portions of the exterior walls and structural elements with approved non-combustible or limited-combustible materials- firewalls, walls, arches, interior structural elements, floors, and roofs entirely or partially made of wood

- IBC: Exterior wall construction made of non-combustible materials and the interior building elements made of any material permitted by this code

- ISO Class 2 (Joisted Masonry): Masonry or fire-resistive constructed buildings with exterior walls rated for not less than one hour and with combustible roofs and floors

Type IV – Heavy Timber

- NFPA: Firewalls, exterior walls, interior bearing walls, and structural elements made of approved non-combustible or limited combustible materials. Solid or laminated wood interior structural elements without concealed space and with allowable dimensions of the NFPA code

- IBC: Construction with exterior walls made of non-combustible materials and interior building elements made of solid or laminated wood without concealed spaces

Type V – Wood Frame

- NFPA: Construction with structural elements, walls, arches, floors, and roofs made entirely or partially of wood

- IBC: Construction with structural elements, exterior walls, and interior walls made of code-permitted materials

- ISO Class 1 (Frame): Buildings with exterior walls, floors, and roofs made of combustible material

Mineral Wool Insulation for Non-Combustible Construction

Mineral wool continuous insulation contributes to non-combustible construction and meets stringent code requirements for energy-efficient building design.

Initially, manufacturers used mined natural rocks to make mineral wool. However, over the years, lower-cost alternatives, like a steel by-product (blast furnace slag) made of spent iron ore and limestone, took natural rock’s place.

Sustainable Slag

Using slag allowed mineral wool to achieve one of the industry’s highest recycled contents, thereby minimizing its environmental impact. The mineral wool industry recycles millions of tons of waste slag every year. Unlike foam plastic insulation, mineral wool does not use blowing agents or flame retardants in its production. In addition, after one month of use, one pound of mineral wool insulation saves the same amount of energy used in its manufacture.

Manufacturing of Mineral Wool

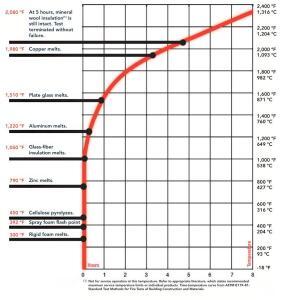

Manufacturers melt rock and slag in cupola furnaces at temperatures above 2,600 ℉, then spin the molten lava into fibers using compressed air and high-speed spinning wheels. The manufacturing process creates mineral wool fibers that can withstand high temperatures, which gives them excellent fire-resistant properties.

The Benefits of Mineral Wool Continuous Insulation

Builders can place mineral wool continuous insulation behind combustible and non-combustible cladding types ranging from high-pressure laminate and fiber cement to brick veneer and single-skin metal panels. Mineral wool CI has several features and benefits that often make it a good choice for a building design: fire performance, thermal performance, moisture resistance, sound attenuation, durability, and permeability.

Mineral Wool CI Contributes to Non-Combustible Construction

Mineral wool insulation will not burn or release harmful smoke and hot gasses during a fire, which makes it an excellent choice for multistory construction. For example, builders often use semi-rigid mineral wool in fire-rated curtain wall systems to minimize the passage of hot gasses and flames from the floor of origin to the above floors.

Mineral wool CI in cavity walls and open-joint facade systems can significantly limit the spread of fire across the exterior wall surfaces of a building.

Mineral Wool Provides Superior Fire Performance

The ASTM E119 test determines the fire performance of building materials based on time and fire temperature. The chart below compares the fire performance of different products. It illustrates that only mineral wool remained intact after five hours and temperatures over 2,000 ℉.

NFPA 285 Fire Test

Manufacturers use the NFPA 285 fire test as an intermediate-scale wall system fire test to measure what happens during a fire when using combustible materials such as foam plastic ci, air barriers, or claddings as part of the exterior wall system. The NFPA 285 test aims to limit fire spread through exterior wall surfaces, to enhance occupant safety and protect the building. Mineral wool is exempt from this test because it is a non combustible material.

The International Building Code (IBC) has recognized NFPA 285 in multiple sections for several years. However, it gained increased awareness when energy standards, like the ASHRAE 90.1, began prescribing CI and requiring air barriers, which are sometimes combustible.

Thermal Performance of Mineral Wool

Mineral wool insulation, with an R-value of 4.3 per inch, can easily meet the specified R-value requirements of the ASHRAE 90.1 to stop thermal bridging and establish an effective R-value in a wall assembly. Moisture exposure will not diminish mineral wool’s R-value. Declining temperatures cause the thermal conductivity of mineral wool to decrease, which improves its R-value.

Moisture Resistance of Mineral Wool

The engineering of mineral wool repels and drains moisture in CI applications. In addition, the design of mineral wool can handle condensation, driving rain, and other moisture on the wall assembly.

Sound Attenuation of Mineral Wool

Mineral wool products provide sound attenuation by blocking and absorbing sound that passes between partition walls and floor/ceiling applications, to improve the indoor environmental quality for the building’s occupants.

Durable Mineral Wool

Durable mineral wool CI repels water and resists UV rays, sleet, rain, snow, ice, and other weather-related events.

Permeable Mineral Wool

Air and vapor-permeable mineral wool CI (perm of 50) allows water/condensation/moisture within the wall cavity to dry towards the exterior.

StoTherm® ci Mineral for Non-Combustible Construction

The StoTherm® ci Mineral EIFS System incorporates the following features to create an advanced cladding system for non-combustible construction with superior thermal performance and advanced acoustic dampening:

- The Sto Thermo Dowel – a pre-assembled fastener and washer designed to minimize thermal conductivity

- Non-combustible, mineral wool exterior CI provides a thermal control layer that resists fire and temperatures exceeding 2000°F (1093°C)

- Continuous-seamless air, vapor, and water-resistant barrier from a single source

- Sto’s high-performance finishes in unlimited finish color selections and multiple textures

StoTherm® ci Mineral complies with crucial fire standards for combustibility and fire resistance:

- NFPA 220: Non-combustible insulation as defined by NFPA 220

- NFPA 285: System complies with mandates for use on all types of construction without height limitation

- NFPA 268: System does not ignite with exposure to radiant heat and complies with requirements for use on all types of construction without setback or height limitations

- ASTM E119: Maintains hourly fire resistance rating of concrete masonry, concrete, and non-load bearing steel frame wall systems

- ASTM E84: Insulation has zero flame spread, zero smoke development

Substrate: Glass mat gypsum sheathing in compliance with ASTM C1177, code-compliant OSB or plywood sheathing, concrete or concrete masonry, existing structurally sound, uncoated brick or masonry wall construction:

1. Air and Water-Resistive Barrier: Sto Gold Coat®

2. Adhesive: Sto BTS® Plus

3. Insulation: Owens Corning Thermafiber® CI-C SC18

4. Attachment System: Sto Thermo Dowel with Sto Thermo Cap Wool

5. Reinforcing Mesh: Sto Mesh (embedded in Sto BTS Plus)

6. Base Coat: Sto BTS® Plus – at least two coats

7. Primer: StoPrimer – Sand or Smooth (optional)

8. Aesthetic choices: Sto Textured Finishes, Sto Custom Cast Finish:

Brick or Wood, Sto Signature Series, and Sto Specialty Finishes

StoTherm® ci Mineral for Non-Combustible Construction

Builders and architects can use StoTherm® ci Mineral for residential, commercial, industrial, institutional, and more for wall non-combustible construction – vital to protecting buildings and occupants from increasing wildfire seasons. StoTherm® ci Mineral incorporates non-combustible, mineral wool exterior CI to create a high-performing cladding system for non-combustible construction with excellent thermal performance.

For more on non-combustible construction with mineral wool systems, contact our Sto professionals today at (800) 221-2397.