Choosing sheen used to be as simple as deciding between a dull or glossy finish. Today, we have three standard sheens–many with additional functionality built-in–and coatings are more advanced than ever. The combination of the two can bring an architect’s vision to life.

Sheen: A Closer Look

The appearance of a coating’s sheen is influenced by several key factors: light interaction, surface texture, material composition, and environmental conditions. The fundamental principle behind the sheen is the reflection and absorption of light. When light hits a surface, some is reflected while some is absorbed, which determines the appearance of the sheen. Glossy surfaces reflect more light, creating a shiny appearance, whereas matte surfaces absorb more light, resulting in a subdued finish.

Surface roughness and texture also play a crucial role in the perception of sheen. Smooth surfaces tend to reflect light more uniformly, enhancing the gloss effect, while rough or textured surfaces scatter light in multiple directions, reducing the gloss and creating a matte appearance. The formulation of the coating itself is another vital factor. The coating’s composition of binders, pigments, and additives affects how light interacts with the surface. Higher binder content typically produces a glossier finish, while higher pigment concentration can create a more matte effect by scattering light.

The angle of incidence, or the angle at which light strikes the surface, can change the perceived sheen. For instance, a surface may appear glossier when viewed from a certain angle compared to when viewed head-on. Environmental factors, such as humidity and temperature, can also impact the final appearance of the sheen. These conditions can affect the coating’s drying process and final texture, influencing its reflective properties.

The Different Sheen Levels

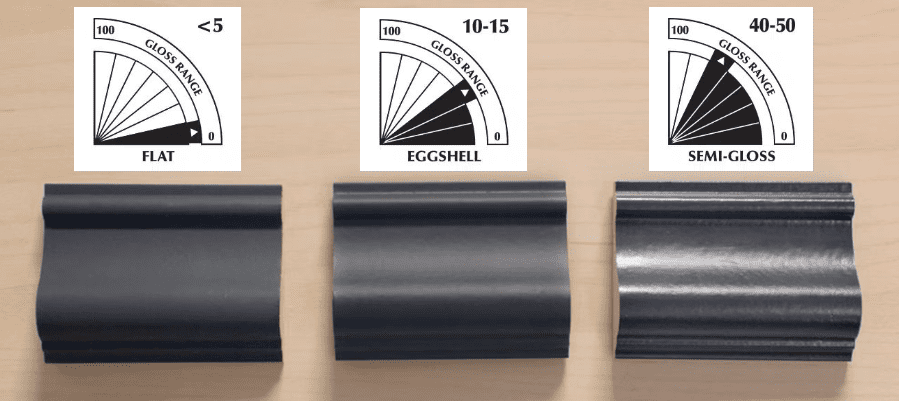

Finishes may go by different names depending on the coating, but there are essentially three standard types: flat/matte, eggshell/satin, and semigloss/high-gloss. Here’s a recap of the pros and cons of each:

- Flat/Matte – Provides a smooth appearance that doesn’t reflect light directly, making imperfections less noticeable.

- Eggshell/Satin – Offers more durability and a slightly higher reflection than matte.

- Semigloss/High-Gloss – Resistant to mildew, dirt, and stains, semigloss is bright and shiny and, as a result, reveals imperfections.

Balancing these factors with aesthetics goals, the building’s location and surface type helps ensure a beautiful finish.

The Importance of the Coating

Sheen is important–it’s the finishing detail! But the right coating will help you tell the story. Sto’s high-performance architectural coatings not only enhance the beauty of your building but also provide superior protection against the elements. Our architectural coating solutions include products that offer fade resistance, protection against mold and mildew, crack bridging, and even self-cleaning properties. All Sto coatings are vapor permeable and low in VOCs. They are engineered to be used in vertical applications, come in various textures and sheens, and can be tinted in an endless array of colors to suit your design needs.

Our architectural coatings include:

- Sto iQ Technology™ – Coatings inspired by nature that provide superior functionality and durability are designed to keep the facade clean, dry, and bright with less maintenance.

- Specialty Coatings – Coatings that offer the ability to create unique aesthetics to enhance the design of your building.

- Traditional – Coatings that preserve the value of buildings by serving as a breathable, durable, attractive layer of protection.

- Elastomeric – Coatings that bridge hairline cracks and increase weather resistance.

- Primers – A variety of primers designed to improve finish coat coverage and promote uniform substrate absorption.

- Sealers – Topcoat sealers that protect and enhance color and fade resistance of Sto coatings and finishes.

Unique Customized Effects that Enhance Curb Appeal

For unique, customized aesthetics combined with performance characteristics, you’ll want to consider Sto Specialty Coatings. Offering a wide range of creative options, Sto Specialty Aesthetic Coatings enhance curb appeal and protect the building. Our Specialty Coatings include:

- StoColor® Metallic – offers the ability to achieve a metallic panel look with various color and texture options. All 15 standard colors can be applied over smooth or textured surfaces, offering versatility and creating a custom look while utilizing standard finishes.

- StoColor® Wood Stain – an acrylic-based stain for use as a topcoat over StoCast Wood and StoSignature® Wood. It provides superior UV protection for long-lasting colors and is available in gloss or matte sheen.

- StoTique® – an exterior and interior coating that achieves an “antique” mottled effect or other custom decorative effects. Use it over existing EIFS, stucco, previously painted wall surfaces, or any Sto textured or smooth finish coating.

- StoColor® Texture – an acrylic-based textured coating used over prepared vertical concrete, stucco, existing EIFS, tilt-up, or masonry surfaces.

Projects that Showcase the Impact of the Right Coating and the Right Sheen

The right architectural coating with the right sheen makes all the difference. Here are a couple of case studies that prove the point.

Sheen in Action: Houston House

Project: Houston House

Location: East Village, New York

Construction Type: New

Systems and Products: StoTherm® ci, Stolit® Milano

Houston House, located in New York City’s East Village, is an excellent example of how sheen can achieve a modern, stylish look while maintaining practicality. The project utilized innovative techniques to replicate the appearance of sleek metal panels, driven by the need for a high-end, contemporary aesthetic that resonates with the vibrant neighborhood.

The building’s finish is designed to mimic the sheen and texture of metal panels. This finish provides a smooth, reflective surface that captures light beautifully, creating an eye-catching facade. The ability to reflect light in a controlled manner gives the building a polished, upscale look, enhancing its visual appeal in the bustling urban environment.

The application process was crucial in achieving the desired metal-like sheen. Skilled applicators meticulously applied the finish in multiple coats, sanding each layer to perfection. The final coat was troweled to create deep grooves, imitating the joints of metal panels. This attention to detail ensured a uniform, glossy finish that convincingly replicates the look of metal.

One of the significant advantages of using a specialized finish over actual metal panels is its superior thermal performance. The system provides continuous insulation, which helps regulate the building’s temperature and reduces energy consumption. Additionally, the finish offers excellent durability and weather resistance, crucial for withstanding New York City’s harsh winters and hot summers.

Moreover, this innovative finish is more cost-effective than traditional metal panels. It delivers the same high-end appearance without the associated expenses, making it a practical choice for developers looking to balance aesthetics and budget. This approach enhances the building’s exterior and contributes to its sustainability and energy efficiency.

In conclusion, the Houston House project demonstrates how modern coating technologies can effectively use sheen to achieve a sophisticated, metal-like appearance. The finish provides a durable, energy-efficient solution that meets aesthetic and practical requirements, setting a new standard for urban residential design.

Coating Can-Do: Steamboat Grande

Project: Steamboat Grande

Location: Steamboat Springs, CO

Construction Type: Renovation

Systems and Products: StoColor® Lotusan®

Located a few steps from the base of the Steamboat Ski area, the Steamboat Grand Resort is a popular luxury resort in Steamboat Springs, Colorado. At an altitude of 6,900 feet, the exterior façade is exposed to 300+ days of sunshine per year and some of the highest snowfall totals in the state. The exterior of this 12-year-old ski resort hotel needed a facelift, and the owners were looking for a solution that would help retain the resort’s curb appeal. It was the perfect project for StoColor® Lotusan®, the super hydrophobic exterior coating that produces a finish with self-cleaning properties using Sto’s Lotus-Effect® technology.

StoColor Lotusan is a flat exterior wall coating modeled on the microstructure of the lotus leaf. The lotus-effect technology, engineered by Sto, imparts super-hydrophobic properties to the coating, which, along with superior self-cleaning properties, resists soiling, mold, mildew, and algae. It also has excellent weather and UV fade resistance.

StoColor Lotusan is a flat exterior wall coating modeled on the microstructure of the lotus leaf. The lotus-effect technology, engineered by Sto, imparts super-hydrophobic properties to the coating, which, along with superior self-cleaning properties, resists soiling, mold, mildew, and algae. It also has excellent weather and UV fade resistance.

Michael Lomas, vice president and general manager of The Steamboat Grand, was pleased with the outcome. “Sto did an excellent job matching the paint colors, and the StoColor Lotusan looks excellent.”

Closing

Sheen is the finishing touch to your vision. It’s no longer an afterthought. In addition to showcasing your design and letting it be all it can be, sheen can contribute to a building’s long-term performance and maintenance. And the right architectural coating with the desired look and functionality combined with the right sheen can be an absolute game changer. Explore the possibilities and get creative using the tools available at stocorp.com.